Trouble finding a product?

Contact us.

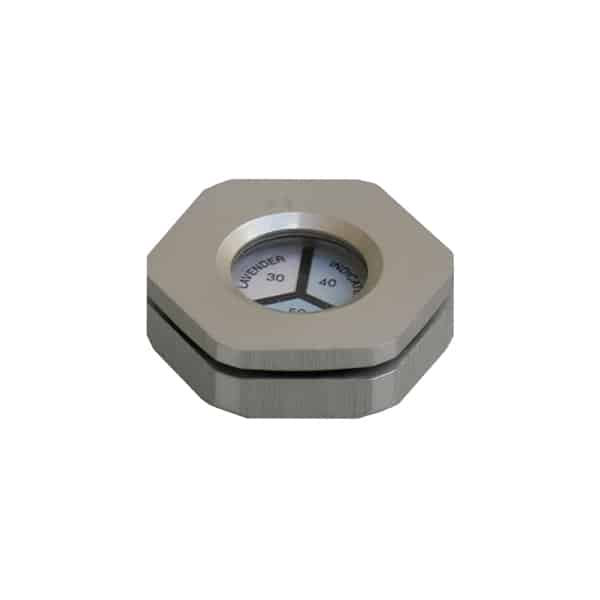

Humidity Indicator Plugs

Humidity indicator plugs are designed for mounting on reusable or long-term storage containers or in any other humidity-controlled enclosure to hold humidity indicator cards and detect changes in the relative humidity of the space being monitored. Electronic humidity sensors similarly monitor humidity; however, a circuit housed inside of the plug may provide data logging, data transfer, easy bulk monitoring, as well as visual indication of the relative humidity level inside of the container.

- Container Access

- Corrosion Prevention

- Humidity Monitoring

- Moisture Control

- Moisture Purging

- Pressure Control

- Shelving & Straps

- Shock Monitoring

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!

What are Humidity Indicator Plugs?

A humidity indicator plug is a device that is installed into an enclosure wall and securely holds a humidity indicator card visibly in its head.

Humidity indicator plugs are made from varying materials, including but not limited to brass with zinc plating, anodized aluminum, and steel. Some may have glass covers – visibly similar to wristwatches – over the humidity indicator card.

Humidity indicator plugs are designed for mounting on reusable or long-term storage containers, in flexible barrier material, in moisture-sensitive electronic or optical equipment, or in any other humidity-controlled enclosure.

They readily detect changes in the relative humidity of the space being monitored by one of two means: Reversible Color-Change and Maximum Humidity Indicator.

How Do Humidity Indicator Plugs Work?

Humidity indicator plugs have an indicator that resides on the outside of the enclosure, while the rear of the plug is open and exposed to the internal environment of the enclosure. This allows the indicator card on the plug to react to the internal humidity level, which can be visually inspected on the indicator on the outside of the enclosure.

What Are Electronic Humidity Sensors?

An electronic humidity sensor is a circuit designed to detect humidity in the space in which it is installed. Typically, these sensors will provide some digital readout of the humidity level or an indication of whether a set threshold has been reached. Additionally, some can record data for greater analysis and better understanding of storage conditions and container designs, as well as more attention to and faster reaction to dangerous humidity levels.

AGM offers two different types:

- AGM Electronic Humidity Sensor

- TA26-1 Electronic Humidity Indicator

What Makes AGM’s Electronic Humidity Sensor Unique?

AGM’s electronic sensor provides the ability for a user to closely monitor one or many containers quickly and efficiently. More than just ease, AGM’s sensor allows a user to record and store data for long periods of time in order to determine potentially damaged containers, optimize storage conditions, and easily know which materials may be damaged and require inspection.

AGM’s electronic sensor:

- Logs temperature and RH every hour

- Has a 20-year battery life

- Provides 20-year data life

- Uses LED visual indications

Benefits Of Using Humidity Indicator Plugs

As receptacles for humidity indicator cards, humidity indicator plugs provide an easy and convenient way of utilizing humidity indicator cards to monitor the internal environments of sealed containers and enclosures without opening the environment.

Why Use AGM’s Electronic Humidity Sensor?

- Humidity indicator cards only provide an instantaneous reading, and many are reversible, so the reading is only good at the time it is read. Meaning, its indication can change throughout the day.

- AGM’s electronic humidity sensor, however, is always logging data, so you can see a complete history of what’s going on in that container over time and at any specific time.

- The electronic humidity sensor will show a blinking red light once your desired preset threshold has been reached.

Why is the Humidity Level Inside of a Container Important?

A lot of items and materials are sensitive to humidity and moisture. During transit, it’s common for such items to be stored inside of containers to protect them and keep them dry.

Some examples include metals that can corrode, optics that will fog up if there’s too much humidity, electronics that can short, etc. There are also contents or items that breakdown and, when they do, release moisture into the sealed enclosure, thereby elevating the humidity level. Therefore, in order to properly preserve these items and materials, when you see a rise in humidity level you know that there’s a problem with whatever is inside of your container.

Is Any Other Equipment Needed to Use AGM’s Electronic Humidity Sensor?

Yes, there are several tools that work in conjunction with the electronic humidity sensor, including:

Activator: An infrared flashlight with a unique light signature. The activator is used to initially activate the sensor and thereafter may be used to trigger a visual indication on each sensor of the environment inside the container.

Interrogator: Used to initially set up thresholds and then, later, download date. This tool communicates with the sensor via infrared and is thus wireless.

Is the Activator Needed or How Else is the Sensor Activated?

The activator is required to initially activate the sensor. Afterward, however, the sensor face may be pressed to display a container’s internal condition.

How Temperature and Humidity Data Transferred to Another Device?

AGM’s electronic humidity sensor transfers data using the interrogator. Data is downloaded as a CSV file to one’s computer. This data can be viewed and analyzed in the appropriate software of your choosing, such as Microsoft Excel.

Industry Applications

Indicator plugs are beneficial for many industries, but are specifically used by those that require storing or shipping in sealed containers that cannot be seen from the outside, or would be compromised if opened.

Custom Engineering Service

No two jobs are the same, why should your solution be? Work with AGM Engineering to get a solution specific to your challenge today.

FAQs

Yes. AGM’s Engineering Department has designed hundreds of modified and custom versions for previous customers.

Yes, you can mount a humidity indicator plug in your bag but you will need the mounting nut version to do this.

All of our humidity indicator plug designs will withstand 10 psig in either direction while our TA284 series is guaranteed to 500 psig outward for high-pressure applications.

Most units are rated to 10 psig in the pressure relief direction. This means the higher pressure is behind the window trying to push the window out of the container. The few vacuum direction tests we have run have shown that the TA356 series at least will also hold 10 psig in the vacuum relief direction.

Both the flange and the mounting nut are 1-3/8” hex shapes. So any suitable hand tool that is capable of engaging a 1-3/8” hex will work. We recommend tightening the mounting nut to 30-40 in-lbs.

We recommend 30-40 in-lbs for all humidity indicators we offer that are made of metal except for the TA28X series, which utilize an NPT thread form. For the TA28X series, a higher torque might be required. For the TA380 series (made of SAN plastic), we recommend 5-8 in-lbs, or just finger tight.

This thread is misleading because it actually has a maximum major diameter of 1.027”. Therefore, the recommended mounting hole diameter is 1.050″ (26.7 mm). This thread is commonly used on the small bung of a 55-gallon drum. The reason our humidity indicators have this thread is that they were initially used most commonly on 55-gallon drums.

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!