Trouble finding a product?

Contact us.

Custom Molded Dessicants

Whether it’s custom bagged desiccant, machined desiccant, or molded desiccant, AGM can provide one-of-a-kind desiccant solutions to meet your unique moisture control requirements.

- Container Access

- Corrosion Prevention

- Humidity Monitoring

- Moisture Control

- Moisture Purging

- Pressure Control

- Shelving & Straps

- Shock Monitoring

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!

Why Use Custom Dessicant?

It’s not uncommon for the design of a project to feature a compact internal volume, packed with all manner of electronic, optic, or mechanical components. Furthermore, what free space is available is often shaped in some strange or complex geometry. Despite the restrictions on any available space, these components must be properly protected against moisture, or risk damage and failure.

Custom molded desiccants, custom bags, and custom desiccators provide are designed and manufactured to specific size, shape, crush strength, and adsorption characteristics to meet the needs of constrained projects.

Benefits of Custom Dessicant

Where bulk and packaged desiccants are not able to provide the necessary protection to a project, custom molded desiccants can. Additionally, to help save space, some AGM molded desiccants are strong enough for us as structural components.

Custom desiccants can solve moisture protection, structural, size constraint, and debris contamination challenges.

Industry Applications

Custom molded and bagged desiccants, as well as custom desiccators are all prominently positioned throughout technical industries, such as aerospace, defense, space, and automotive to provide moisture protection in restricted spaces.

AGM Custom Pressed Desiccant: H2OLock

H2OLock features high compressive strength and moisture adsorption control to provide a unique desiccant capable of protecting advanced equipment from moisture, while delivering structural support for reducing overall product weight

H2OLock Pressed Desiccants

What is AGM's pressed desiccant, H2OLock, and what is it best used for?

What Can H2OLock Do For You?

AGM pressed desiccants provide the moisture adsorption you need in the shape you need it. Aren’t sure what you need? Ask an AGM engineer.

What is H2OLock Pressed Desiccant?

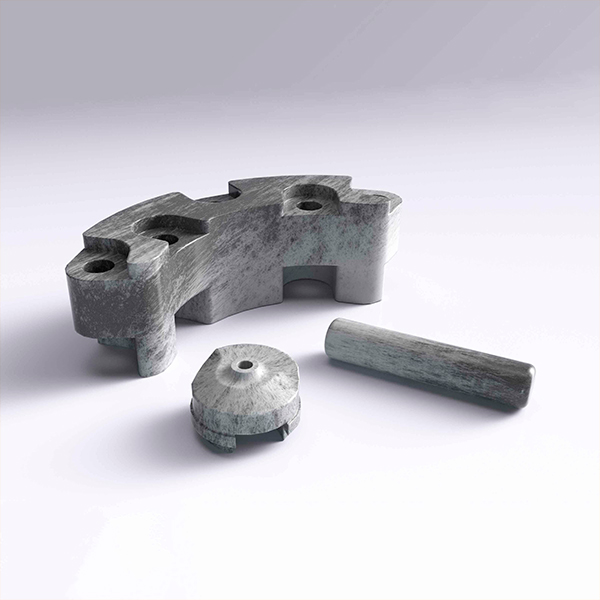

AGM H2OLock pressed desiccant combines moisture adsorption with compressive strength. Due to its composition, H2OLock may be machined into almost any geometry needed to fit a project.

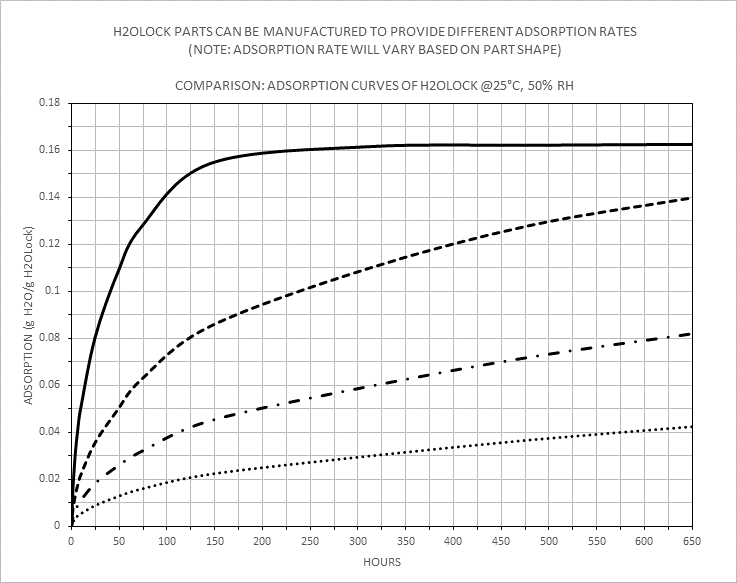

H2OLock Pressed Desiccant Adsorption Rate

AGM’s H2OLock pressed desiccant is a suitable replacement for NatraSorb 900 and other similar desiccant products. H2OLock pressed desiccant provides a balance between strength, adsorption rate, moisture capacity, and thermal resistance.

Shaping and Form Factor: H2OLock Pressed Desiccant

H2OLock pressed desiccant can be machined and shaped to fit any project needs. Additionally, standard shapes are available. These include tablets and cylinders.

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!

FAQs

Custom desiccants provide moisture control when standard bagged or canister desiccant is inadequate to your project’s needs due to size, shape, or moisture adsorption capability. Custom desiccants are commonly formed, pressed, or bagged desiccants that are shaped to fit your project without requiring you to perform a redesign. These desiccants are intended to properly fit into the cavities and open spaces of a specific product or its housing. An example of a custom desiccant is AGM’s H20Lock Pressed Desiccant.

AGM manufactures two main types of custom desiccants: H20Lock Pressed Desiccant and Custom Desiccant Bags.

H2OLock Pressed Desiccant is a is a composite desiccant designed to provide an optimum balance between strength, adsorption rate, moisture capacity, and thermal resistance. H2OLock is comprised of 4A molecular sieve and heat resistant binders. The desiccant’s composition provides H2OLock with:

- A serviceable maximum temperature of 150C (302F)

- Compressive strength of 6,000 psi

- High-performance moisture adsorptive capabilities

Due to its durability, H2OLock can operate as a structural component and moisture adsorber in one, frequently replacing plastic and metal parts, insulators, shock pads, and other pieces.

AGM can produce Custom Desiccant Bags in non-standard bag sizes using a benchtop heat sealer, up to 11.3″ x 11.3″ (interior dimensions). Bags may also be handsewn. The bag material is coated Tyvek® and may be filled with molecular sieve or silica gel. Bentonite clay may also be used; however, we advise you to contact AGM’s Engineering Department for bentonite clay availability.

AGM also offers custom desiccant bags in 10, 15, and 20 lbs weights for larger volumes. A variety of sizes, bag materials, and configurations are available upon request.