Trouble finding a product?

Contact us.

Ultra High Flow Breather Valves for Rapid Decompression

AGM’s ultra high flow breather valves, otherwise known as magnet valves, provide greater flow rates compared to standard spring breather valves. Ultra high flow valves are designed to provide differential relief to large containers and any container during rapid decompression in aircraft.

- Container Access

- Corrosion Prevention

- Humidity Monitoring

- Moisture Control

- Moisture Purging

- Pressure Control

- Shelving & Straps

- Shock Monitoring

Why Use High Flow Breather Valves?

Ultra high flow breather valves (magnet breather valves) are designed to exhaust pressure differentials during rapid decompression in flight. Specifically, these valves flow a massive quantity of air to protect cargo, containers, transit vehicles, and people during rapid decompression. As a result, cargo and containers remain undamaged, potential damage to transit vehicles is minimized, and the risk to nearby persons is mitigated.

Ultra high flow breather valves provide a lot more airflow in comparison to traditional spring breather valves. This means that these magnet breather valves can exhaust pressure differentials in enclosed or sealed containers much more quickly and safely in comparison. Such quick relief is especially important during rapid compression events occurring in air transit.

What are Ultra High Flow Magnet Breather Valves?

Ultra high flow magnet breather valves provide greater air flow rates in comparison to traditional breather valves, and are thus able to relieve large pressure differentials.

Let's Get Your Project Moving Forward!

What is Rapid Decompression in Aircraft?

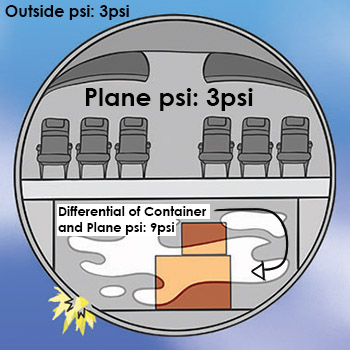

Rapid decompression during flight is the event in which air pressure inside of a plane quickly and significantly drops to meet that of the air pressure external to the aircraft. This typically occurs during some breach in the plane’s fuselage while in the air. In general, rapid decompression events are categorized as occurring within 0.5 to 30 seconds. Furthermore, roughly 40 or more such events happen per year.

During any decompression event, a pressure differential is generated between the pressure inside of a sealed space and that of the atmospheric pressure external to the enclosure – which varies with elevation. If the magnitude of the differential is greater than the pressure or vacuum rating of a given enclosure (sealed case or container, plane fuselage, water bottle, chip bag, etc.), the enclosure will rupture. In most situations, these differentials are small and generate slowly; they are not a threat to most enclosures. However, during rapid decompression, the differential generates very quickly. Further, the magnitude of this differential – notably when planes are at altitude – is often significantly greater than the rating of an enclosure containing cargo. For these two reasons – rapid generation and critical magnitude – protecting a sealed space from damage requires a breather valve that can flow a lot of air very quickly. This is the specific scenario for which AGM’s ultra high flow magnet breather valves were designed.

Sealed cases and containers in a plane’s hold can rupture under rapid decompression, and their contents can be damaged or lost. This is especially concerning during the transport of delicate, calibrated, or high-value equipment, such as satellite infrared optics or guidance systems for munitions and spacecraft. A similar concern arises when transporting large cargo containers, where the internal volume of the enclosure is so great that relieving pressure differential under even normal conditions requires more airflow than a standard spring breather valve can provide. Such containers may carry technical equipment, as previously mentioned, but may also carry goods and medicines, such as vaccines. In such cases, the container rupturing can mean the loss of life saving medicines or necessary rations.

How are Ultra High Flow Breather Valves and Rapid Decompression Connected?

Due to the rate at which rapid decompression events occur, it is necessary to flow a great amount of air in a short period of time. In this way, it is possible to avoid damage to a sealed container, as well as its contents.

During rapid decompression events, any sealed containers can explode or fly apart due to the fast pressure buildup. Therefore, it’s necessary to reduce that pressure very quickly before the container’s pressure threshold is reached. This reduction of pressure to safe levels can be achieved using AGM’s ultra high flow breather valves, known as magnet valves. AGM’s ultra high flow breather valves fully open in 0.04 of a second to reduce pressure very quickly.

Rapid Decompression and Ultra High Flow Breather Valves

Ultra high flow breather valves are used to safely relieve pressure up to rapid decompression events.

How Fast Do Ultra High Flow Breather Valves Open?

Due to the use of rare earth magnets in their construction, ultra high flow breather valves (magnet valves), are able to open fully and flow more air in comparison to common spring breather valves. Ultra high flow breather valves can achieve such performance due to the physics associated with magnetic attractions; namely, the inverse square law of force. In concept, the attractive force between the magnets in the breather valve decreases as a square of the distance between them. As a result, it takes only 0.04 of a second for an AGM magnetic ultra high flow breather valve to fully open once the set pressure or vacuum threshold has been met.

Ultra High Flow Breather Valve Whitepaper

How to Safely Relieve Differentials During Rapid Decompression

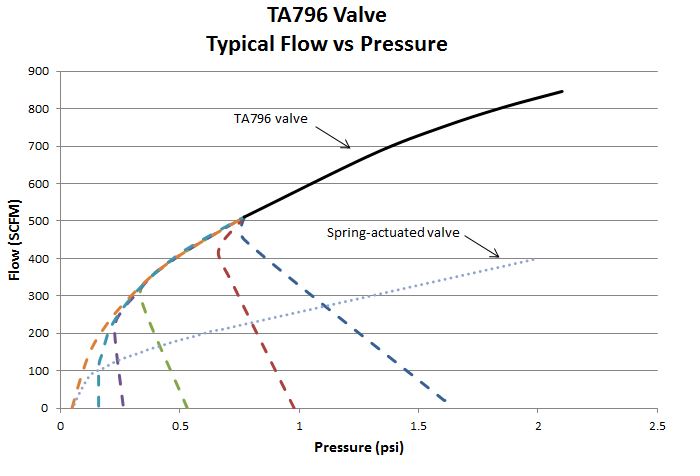

Commonly referred to as magnet valves, AGM’s Ultra-High-Flow Relief Valves, shown above on this page, are magnetically actuated to provide flow rates specifically capable of venting a container to relieve catastrophic pressure buildup during decompression events. Unlike conventional spring-actuated valves, AGM magnet valves fully open once the desired pressure threshold is reached, to achieve full airflow almost instantly.

How Long to Safe Pressure Levels?

Typically, a spring breather valve takes about five times longer to relieve a pressure differential in comparison to one of AGM’s ultra high flow breather valves. This is extremely important during rapid decompression in aircraft, where a sudden pressure drop from 11 psi to 3 psi can occur in less than 0.5 seconds.

How Do Ultra High Flow Valves Work?

AGM’s ultra high flow breather valves utilize rare earth magnets (giving rise to their colloquial name magnet valves) rather than springs to facilitate their crack and release. This construction enables a magnet valve to fully open near instantly once the cracking pressure is reached. As a result, the valve will provide a massive amount of airflow in approximately 0.04 of a second.

Such quick response is due to physics: magnetic force is inversely proportional to the distance between two magnets squared. This is the secret to AGM’s ultra high flow breather valves’ high performance.

Conversely, a spring breather valve must account for Hooke’s Law and the spring’s restorative force. This creates constant resistance to the airflow and, as a result, the spring breather valve cannot not provide full flow as quickly, nor for as long, as a magnet valve.

Can Ultra High Flow Breather Valves be Used on Any Container?

Ultra high flow breather valves are best suited for containers of about 250 cubic feet in volume or less during rapid decompression events. However, these breather valves are also suitable for use protecting containers during normal air transport conditions and not only during rapid decompression events. Spring breather valves are sufficient for most containers, but magnet breather valves can be used to protect large containers.

AGM Ultra High Flow Magnet Breather Valve Performance

- Relieve pressure in about one-fifth the time compared to spring-actuated valves

- Provide Dramatically higher airflow rates at any given pressure differential compared to spring-actuated valves

- Are capable of relieving catastrophic pressure with a single valve per container

- Enable smaller, lighter, and ultimately less expensive container construction

- Magnets do not interfere with aircraft navigation and control systems

How Do Mag Valves Compare to Other Rapid Relief Solutions?

Other solutions for rapid relief are blow-out panels or rupture discs. These are one-time use products. Once they burst to relieve pressure, they’re used up. Additionally, such products are fragile, so it’s easy to accidentally break them during handling.

Comparatively, AGM ultra high flow breather valves are resealable; meaning, no matter how many times they open, they’ll reseal themselves to be used again automatically. Furthermore, due to their robust construction, they don’t break easily and are better suited to rough handling or usage conditions.