Trouble finding a product?

Contact us.

Humidity Indicators, Monitoring, and Measuring

Don’t let your equipment and product ruin as a result of moisture ingress. Humidity indicator cards and plugs provide external monitoring of humidity levels inside of containers.

- Container Access

- Corrosion Prevention

- Humidity Monitoring

- Moisture Control

- Moisture Purging

- Pressure Control

- Shelving & Straps

- Shock Monitoring

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!

Humidity Indicators, Plugs, and Sensors

AGM designs, manufactures, and distributes indicators and sensors for the detection and monitoring of moisture content in sealed enclosures.

What are Humidity Indicators?

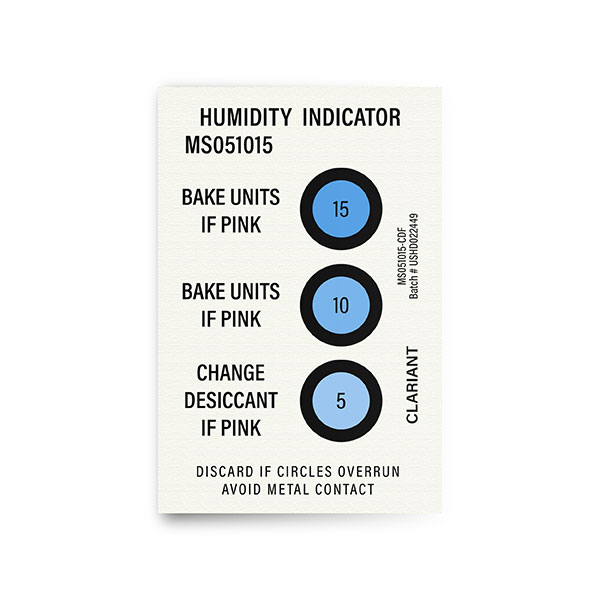

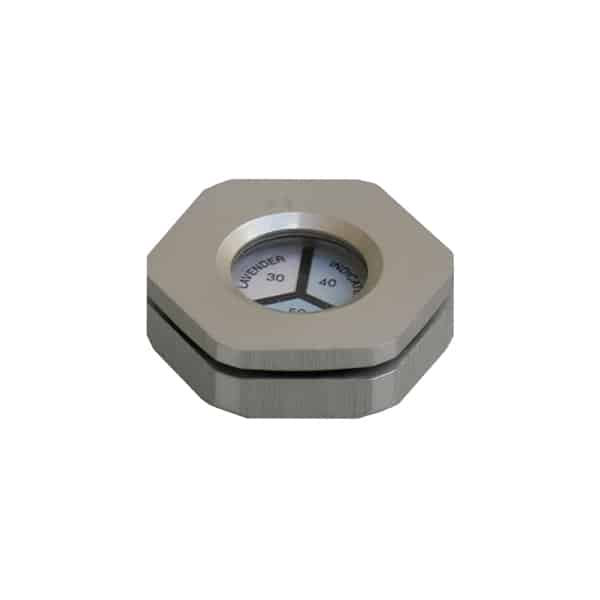

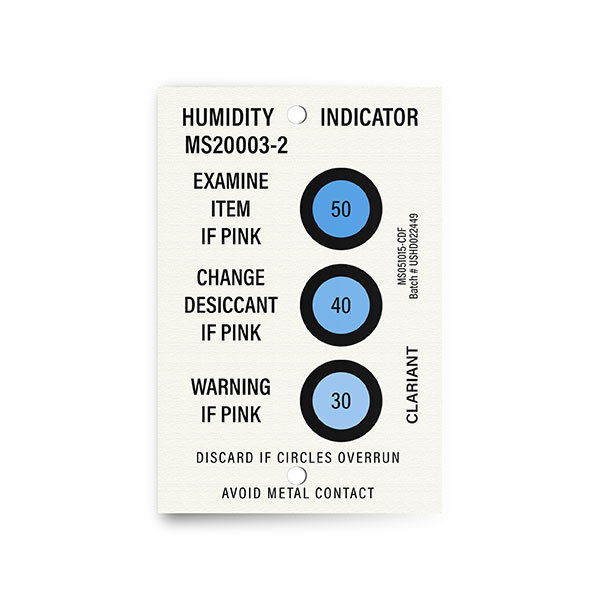

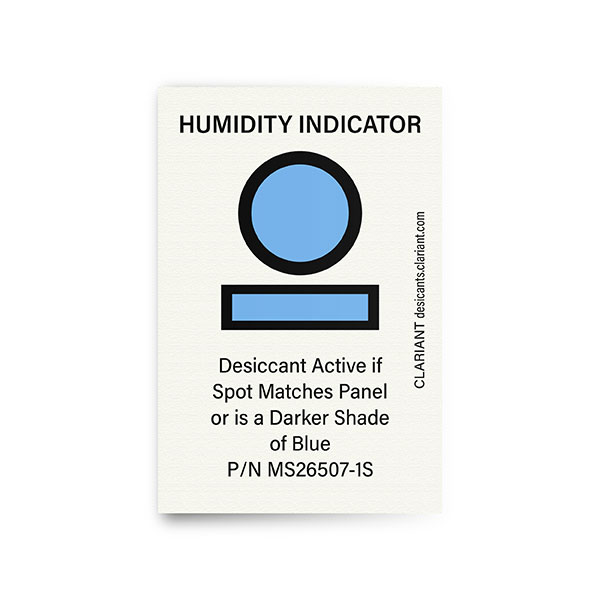

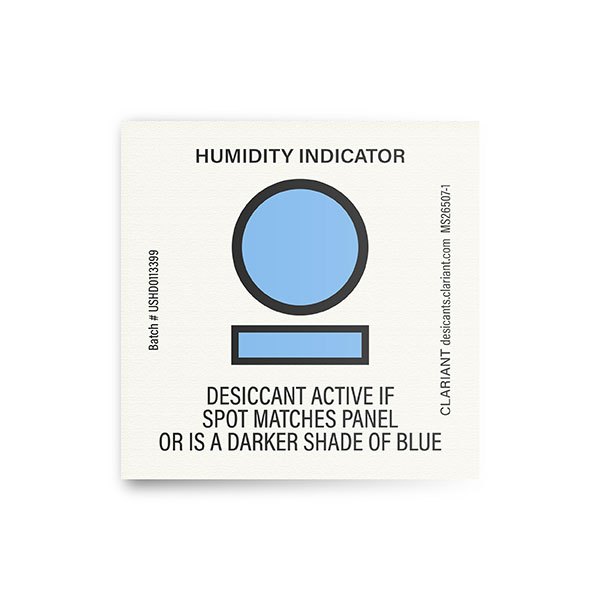

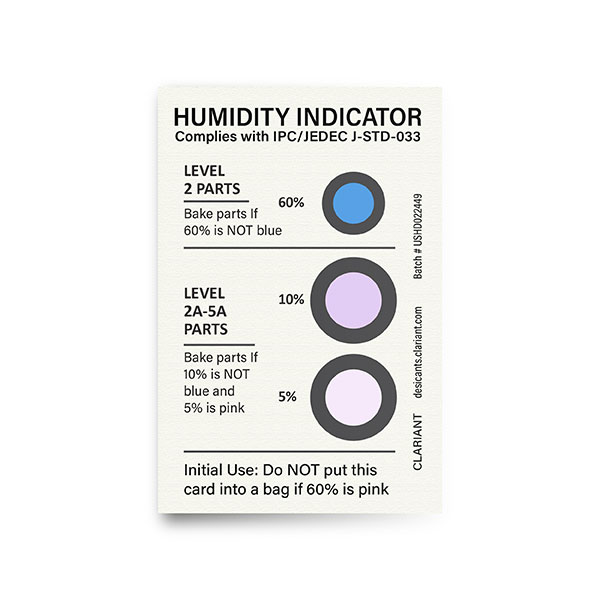

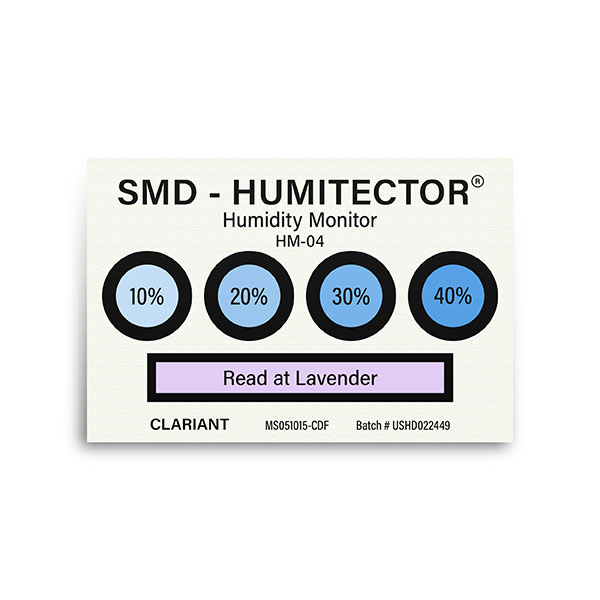

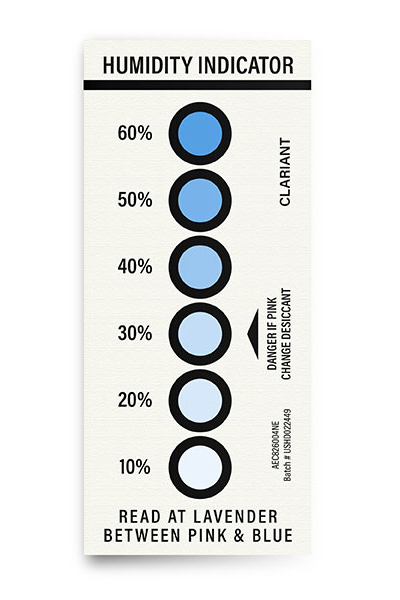

A humidity indicator is an object, device or mechanism that visually signals the relative humidity level of its given environment.

How Do Humidity Indicators Work?

Humidity indicators and sensors employ chemical change or electronic sensing to measure humidity.

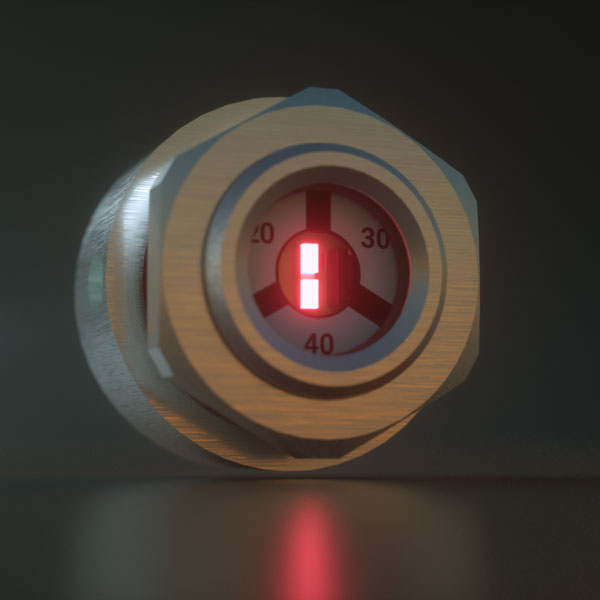

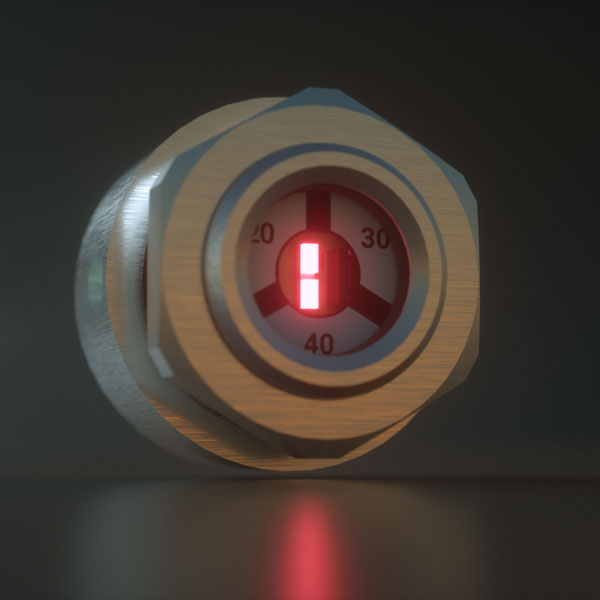

Electronic Humidity Sensor

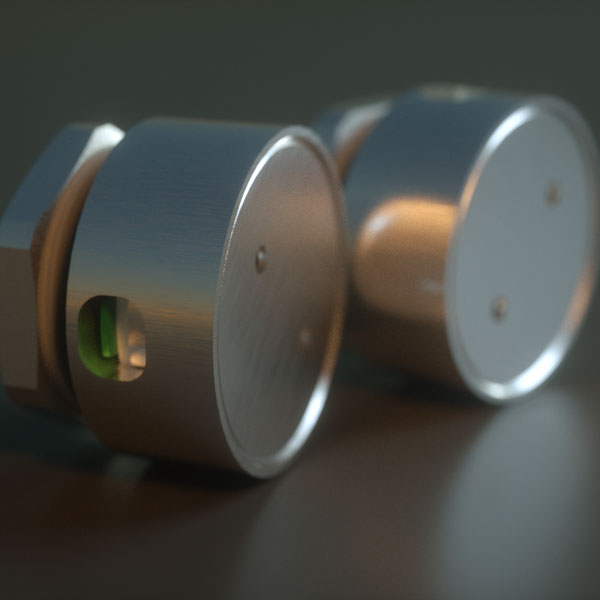

AGM’s Electronic Humidity Sensor (EHS) delivers extended humidity monitoring and indication for sensitive equipment in the most extreme storage conditions.

Key Features Include:

- 20-year battery life

- Hourly data logging with memory for 20 years

- Data can be downloaded from the sensor to Excel via infrared without removal from the container

- Compact size – fits into a standard 1” hole

- Rugged design

- Backup passive color-change humidity indication card

AGM's Electronic Humidity Sensor (EHS)

Initially designed for the U.S. Army to monitor munitions in storage, AGM's electronic humidity sensor allows easy bulk monitoring and recording of sealed containers in any industry.

Why Use Humidity Indicators and Sensors

In order to ensure that the contents of sealed spaces remain in good health without exposing a container’s contents to potential contamination or damage.

Humidity indicators enable quick, easy visual inspection of the humidity level of an enclosed environment from the outside.

Often in the aerospace and many other industries, an enclosure is sealed to protect the contents inside, either for shipping and transit, or permanently if the contents are integral to the operation of the item. These contents frequently include electronics, optics, perishables, or items that may otherwise be negatively impacted when in contact with debris or moisture above a certain level

What is AGM's Electronic Humidity Sensor (EHS)?

AGM’s Electronic Humidity Sensor (EHS) delivers extended humidity monitoring and indication for sensitive equipment in the most extreme storage conditions.

Using AGM's Electronic Humidity Sensor

AGM’s electronic humidity sensor can be used with the Activator and Interrogator peripheral hardware to assist in quick monitoring of large groups of containers, and to program and download data from specific sensors.

Why Monitoring Humidity Levels Is Important

In order to ensure that the contents of sealed spaces remain in good health without exposing a container’s contents to potential contamination or damage.

The Security of the Electronic Humidity Sensor

Developed in conjunction with the U.S. Army for long-term munitions storage, the EHS displays its status via a single colored light when prompted either by directed infrared light or by touching the sensor.

Industry Applications

Humidity indicators and sensors are used throughout many industries to quickly and easily monitor the health of sealed contents. For example, humidity indicators may be used on military munitions boxes, or on storage and shipping containers for infrared optics assemblies like those found on many imaging satellites. A few examples include:

- Monitoring the internal humidity levels in power transformers

- Monitoring gas streams post desiccation and pre-combustion in energy plants

- Monitoring humidity levels around pharmaceuticals in storage and during transport

- Monitoring humidity levels around machine components during storage and transport

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!