Trouble finding a product?

Contact us.

Bulk Desiccants

Our bulk desiccants remove moisture in air-drying systems and a variety of other applications. AGM offers silica gel, activated alumina, clay, and molecular sieve.

- Container Access

- Corrosion Prevention

- Humidity Monitoring

- Moisture Control

- Moisture Purging

- Pressure Control

- Shelving & Straps

- Shock Monitoring

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!

What are dessicants?

Desiccants are hygroscopic materials that adsorb moisture from the air. Desiccants are often used to create and maintain dry spaces, like the housing of an aerial camera, the inside of a shipping container or even a shoebox. Typically used in transport, storage or maintenance of materials and products, desiccants are used to keep everything from gym shoes to military munitions dry.

Examples of common desiccants include:

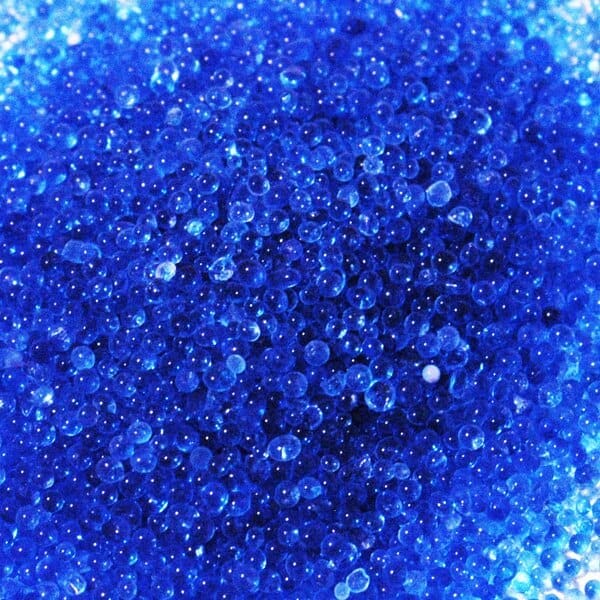

- Silica gel

- Molecular sieve

- Activated Alumina

How do dessicants work?

Desiccants adsorb and trap moisture from the air through the process of adsorption (not to be confused with absorption). In adsorption, water molecules in the air bond to the surface of desiccants. Desiccants hold these water molecules so that they cannot damage moisture sensitive contents that are near the desiccants.

However, desiccants cannot hold an indefinite amount of moisture. Over time, an amount of desiccant will saturate and will no longer attract and hold more moisture. At this point the desiccant load must be changed to prevent moisture damage to cargo or contents.

Did you know, that commonly available desiccants can hold up to a maximum of 35% of their weight in moisture before losing their effectiveness? Using desiccant to protect the contents of a package, container or enclosure helps reduce or eliminate the damage caused by moisture, including mold, corrosion and short circuits. Desiccant is usually the most cost-effective way to remove moisture, both initially and over extended periods of time.

Types Of Bulk Dessicants We Carry

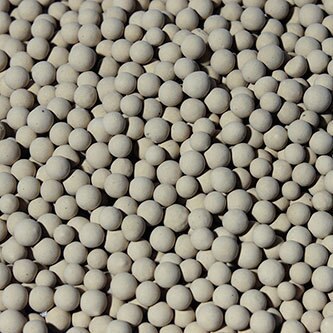

AGM stocks several different types of each of the following desiccants:

- Silica Gel

- Molecular Sieve

- Activated Alumina

Other desiccants, such as montmorillonite clay or activated carbon may be sourced on an as-needed basis. This is because the vast majority of circumstances may be adequately handled more cost effectively using one or a combination of the above three.

What Are Desiccants Used For?

Desiccants are commonly used to keep products dry and safe from harmful exposure during storage and transport.

In order to achieve optimal protection, desiccants should be used within a closed/sealed moisture barrier or a rigid/sealed container. Humidity indicator cards are generally placed inside the container to show the humidity level and to indicate when the desiccant needs to be replaced.

Dessicant Sizing & Selection Criteria

Standard sizes for unit bags are as follows: 1/6, 1/3, 1/2, 1, 2, 4, 8, 16, and 80 units. A unit is roughly one ounce of desiccant material.

- Standard sizes for packets: 1/4, 1/2, 1, 2, 3, 5, and 10 grams.

- Standard sizes for canisters: 40 grams.

Custom sizes are available to fit your packaging needs, though such sizes typically carry a significant minimum order quantity — contact us for more information.

For help determining how much desiccant you need, see AGM’s Desiccant Calculator.

How to choose the right desiccant?

To select an appropriate desiccant, you will have to determine:

- The conditions of maximum product integrity

- The size and type of container used

- The actual conditions (temperature and relative humidity)

We recommend visiting our blog on how to select the right desiccant for more detailed information about each of our desiccant products, their absorption rates and their absorption capacity.

Selecting the right desiccant can be tricky, that’s why AGM has an entire division dedicated to desiccants and their use. In addition, AGM offers a moisture analysis service that takes into account the wide range of variables necessary to prescribe desiccant combinations that maintain targeted humidity-level goals for any storage duration.

For questions about desiccants or our moisture analysis service, please contact us and we will be happy to assist you.

Industry Applications

There are simply too many things to list here to be anywhere near comprehensive. However, some of the largest users of desiccants are in the industrial, pharmaceutical, and electronic components packaging industries. However, desiccants are essential to the safe shipping and storage of things as diverse as optics equipment for pace exploration, military munitions, and family photo albums the world round.

Custom Engineering Service

No two jobs are the same, why should your solution be? Work with AGM Engineering to get a solution specific to your challenge today.

FAQs

In desiccant terminology, a “unit” is a quantity of desiccant defined in the U.S. Military’s specification (MIL-D-3464E) for packaged desiccant products.

Under this specification, a unit is the quantity of desiccant which will adsorb 3.00 grams of water vapor at 20% relative humidity or 6.00 grams of water vapor at 40% relative humidity at 77°F (25°C).

It may also be helpful to think of a unit as equating to approximately one ounce of material. More specifically, a one unit bag of Desi Pak® (clay) contains approximately 33 grams per bag, a one unit bag of Sorb-It® (silica gel) contains 26 grams per bag, and one unit bag of Tri-Sorb® (molecular sieve) contains 32 grams per bag.

How much desiccant you need will depend on the following factors:

• Volume of air space to be desiccated

• Nature of the material to be protected

• Moisture surrounding the package

• Type of desiccant to be used

• Length of time for protection

• Atmospheric conditions (temperature and relative humidity) when/where the product is sealed and during subsequent shipment and storage

Our Desiccant Specialists will ask a number of questions to determine responses to the above information so they can calculate which type and size of desiccant will work best for the particular application. Contact us to get started!

You may use our Desiccant Calculator to determine the amount of desiccant for your application.

For further information on how to determine the amount of desiccant required for your application, visit our blog.

Yes, some desiccants are toxic. If you accidentally consume desiccant, seek immediate medical attention or call poison control!

Desiccants are generally packaged in bags, packets, or canisters. Packets are sometimes referred to as “sachets” or “pouches.”

Desiccants in bags are commonly referred to as industrial desiccants. They are primarily used by industry because their medium to large size enables them to adsorb moisture in heavy-duty applications. However, these bags are commonly used in non-industrial applications as well.

Bagged desiccants are available in:

• Tyvek® (heat sealed)

• Kraft paper (heat sealed)

• Heavy, non-woven rayon/polyester blend (string sewn)

The term “bagged” desiccants commonly refers to any desiccant which is packaged by the unit.

Desiccants in packets or canisters are commonly referred to as pharmaceutical desiccants. They are primarily used by the pharmaceutical industry because of their small size. However, other industries, such as electronics, optics, and food packaging, utilize these packets and canisters as well.

Packet desiccants are available in:

• Tyvek (heat sealed)

• GDTII (heat sealed)

You need a humidity indicator card if you are concerned as to whether or not the desiccant in your package is still active. Desiccant becomes inactive when it has adsorbed as much moisture as it can for the conditions it is being exposed to. This can occur under the following conditions:

- If your package is not properly sealed.

- If you don’t use enough desiccant in your package to draw down the relative humidity.

- If the barrier material (e.g. plastic bag) you use to package your product has a high moisture vapor transmission rate (which means that a significant amount of humid air is entering your package through the barrier material itself).

Find what you're looking for

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!