In technical industries like aerospace, it’s rare to find an easy one-size-fits-all solution. As ubiquitous as desiccants are, even standard desiccant solutions are sometimes not enough to adequately deal with the moisture and humidity needs of specialized applications. That’s where customized desiccants fly high.

When custom desiccants may be a better option:

- The volume of available space is limited

- The shape or geometry of that available volume is complex or nonstandard

Volume of Available Space

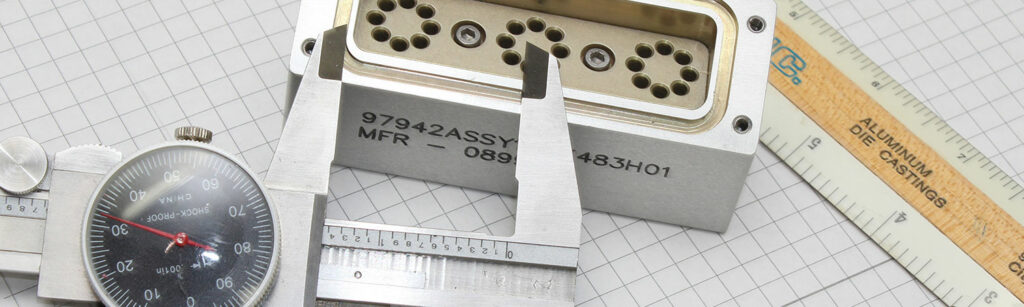

In the aerospace and defense industry, among many others, it’s often important to minimize the weight of an object to improve performance and lower shipping costs. However, reducing weight frequently translates to designing enclosures and whole bodies with restricted overall sizes and strict tolerances. As a result, there simply isn’t a whole lot of spare room available.

However, moisture mitigation is a necessity regardless of the space available, especially in electronics and optical enclosures. In such cases, standardized desiccant products often aren’t sufficient or capable of adequately protecting against moisture ingress, given the limited space available for their install.

Shape of the Available Volume

More often then not, what volume is available is in some non-standard shape – generally, whatever space is leftover after everything has been stored or assembled. As a result, these shapes can complicate the installation of desiccators or desiccant bags, like fitting square pegs in round holes.

Custom Desiccant Options

The alternative option is, of course, customized desiccant products. Such desiccants include:

- Custom Desiccant Bags are built to the shape and size of available volumes and filled with bulk desiccants, such as silica gels or molecular sieves.

- Pressed Desiccants, are desiccants themselves and formed to a size and shape to fit available volumes, while providing moisture protection and, in some case, may be used as structural supports inside of a product.

- Molded Desiccants, are formed through various methods, including injection molding. Specifically, injection molding allows for desiccants to occupy up to 100% of available space, as well as large orders at lower prices.

Custom Desiccant Bags

- Handsewn Desiccant Bags

- Handsewn desiccant bags are typically employed for dehumidifying larger air volumes and may be filled with 10, 15, or 20lbs or silica gel or molecular sieve. They are available in a variety of woven cover stock materials dependent upon the application and location of use. Additionally, these bags may be manufactured in a wide range of sizes. These bags are also commonly manufactured in non-standard shapes. Contact AGM with your dimensions.

- Heat Sealed Desiccant Bags

- Generally used for smaller spaces and lower quantity applications, Tyvek-coated cover stock materials are heat sealed. They may be manufactured with up to an internal dimension of 11.3” x 11.3”, and filled with silica gel, molecular sieve, or bentonite clay. Like the handsewn bags, the heat sealed bags are frequently designed and manufactured in non-standard sizes and shapes.

Pressed Desiccants

- H20Lock Advanced Desiccant

- AGM’s branded H20Lock Advanced Desiccant is a pressed composite desiccant featuring a crush strength of 6,ooo psi and a maximum temperature rating of 302°C. This desiccant is designed to be placed directly into an application and with potential for use as a structural support. This is of special benefit when virtually no space is available. The desiccant may be used to replace plastic or metal parts, shock pads, or insulators, and/or attach directly to PCB boards or other components to provide moisture protection. Finally, H20Lock is Available in several polyhedral shapes and disks – or pucks – and may be machined for a more precise fit.

Molded Desiccants

- H2OLock Molded Desiccant

- AGM’s molded desiccant is made from a combination of 4A molecular sieve, nylon binder, and various other proprietary additives. As a result, the desiccant material is highly moldable, enabling the final product to conform to customer specified sizes, shapes and thicknesses. This combination of materials delivers optimized adsorption, strength, and form capabilities to best meet customer needs.

Contact AGM

For help desiccating your project, call AGM at 520.881.2130 or email us.