Trouble finding a product?

Contact us.

H2OLock-ADV Advanced Desiccant

Description

H2OLock-ADV Standard Shapes

AGM stocks H2OLock-ADV in standard sizes for customers who require rapid delivery of samples for evaluation.

|

H2OLock-ADV, AGM P/N

|

Dimensions (Inches, Nominal)

|

Description

|

|

645120

|

2” Diameter X 1” Tall

|

Puck

|

|

645105

|

2.75" Long x 1.10" Wide x 0.75" Tall

|

Block

|

|

645200

|

2.75" Long x 1.10" Wide x 1.00" Tall

|

Block

|

|

645075

|

0.34” Diameter X 0.20” Tall

|

Tablet

|

Strength, Adsorption, and Form Factor Combine in AGM’s H2OLock-ADV Pressed Desiccant

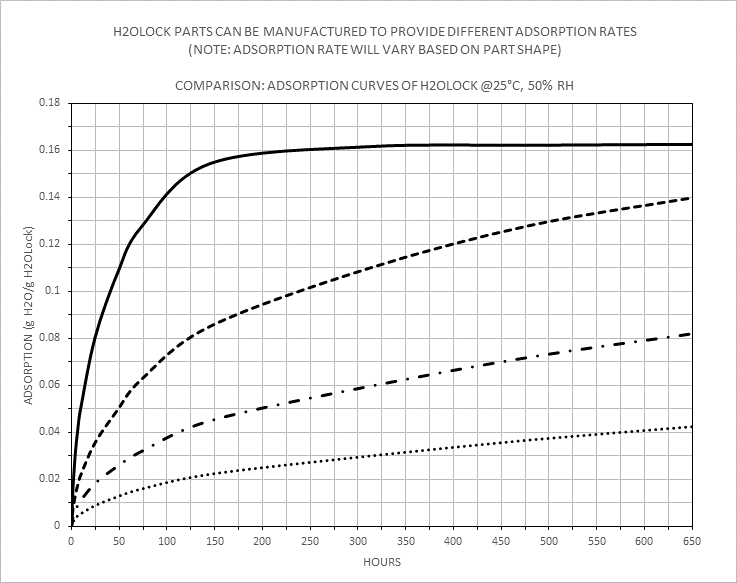

H2OLock-ADV features high compressive strength and moisture adsorption control to provide a unique desiccant capable of protecting advanced equipment from moisture, while delivering structural support for reducing overall product weight. Furthermore, the composition of H2OLock-ADV allows the desiccant to be compressed or machined into varying sizes and shapes, ensuring a proper fit for products with volumes of nearly any size or geometry.

H2OLock-ADV pressed desiccant is available in custom made to order sizes and shapes as well as desiccant pucks. AGM’s H2OLock-ADV pressed desiccant is a suitable replacement for NatraSorb 900 and other similar desiccant products. H2OLock-ADV pressed desiccant is designed to provide an optimum balance between strength, adsorption rate, moisture capacity, and thermal resistance.

How it’s Made: A Composite Desiccant

H2OLock-ADV is a composite desiccant comprised of 4A molecular sieve and heat resistant binders. The desiccant’s composition provides H2OLock-ADV with:

- Serviceable Temperatures:

-

- Continuous maximum: 150°C (302°F)

- Short duration maximum: 350°C (662°F)

-

- Compressive strength of 6,000 psi

- High-performance moisture adsorptive capabilities

Due to its durability, H2OLock-ADV can operate as a structural component and moisture adsorber in one, frequently replacing plastic and metal parts, insulators, shock pads, and many other pieces.

Ideal for Restricted Spaces and Complex Geometries

H2OLock-ADV’s composition allows for shaping by molding directly to size or machining the desiccant in the factory. This feature makes H2OLock-AV pressed desiccant ideal for moisture control in projects with demanding space and shape constraints.

Moisture Capacity

At 25°C (77°F) with 50% relative humidity, H2OLock-ADV can adsorb up to 2.9 grams of water per cubic inch.

What Makes H2OLock-ADV Pressed Desiccant Different from Other Solid Desiccants?

H2OLock-ADV pressed desiccant is typically used when space is limited, or the desiccant’s shape is important. AGM's pressed desiccant is machinable and thus may be made to conform to complex and custom shapes in a range of sizes.

Additionally, on a per volume basis, H2Olock-ADV pressed desiccant has a greater adsorption capacity in comparison to traditional bagged desiccant or molecular sieve beads in a container. Furthermore, because it’s a solid, the desiccant may be secured in place using adhesives, screws, or some other fastening method.

Finally, unlike many other solid desiccants, H2OLock-ADV may be produced in high or low quantities as the result of AGM’s tooling processes.

Is H2OLock-ADV Non-Dusting?

Yes, AGM H2OLock-ADV pressed desiccant is non-dusting and exceeds the Type II desiccant dusting requirements outlined in MIL-D-3464E. As such, H2OLock-ADV may be used safely and without concern throughout an install. This enables H2OLock-ADV’s use in electronics and many other areas.

Desiccant Regeneration: H2OLock-ADV Pressed Desiccant

Regenerating desiccants can be an attractive solution compared to constantly purchasing more desiccant. Below, we provide a quick summary of the process for regenerating H2OLock-ADV desiccants (note that the process differs between desiccant types). For greater details of the process (i.e. temperatures, vacuum levels, heating durations, etc.) see the Regeneration Instruction's PDF in the next section).

Required Equipment:

- Vacuum Oven

- Roughing Pump

- Vacuum Pump

- Airtight Container

Basic Regeneration Procedure:

- Place H2OLock-ADV pieces into heated oven

- Bring oven to required vacuum level

- Heat the desiccant pieces for a minimum of 24 hours

- Take out a piece, weight it and record the weight.

- Place piece back into the oven and continue to heat desiccant for another 6 hours

- Weigh the same desiccant piece again.

- If the weight has decreased by greater than 0.1%, replace the piece and continue to cook another 6 hours

- If the weight has decreased by less than 0.1%, then the desiccant is considered regenerated

- Transfer all pieces to the container to cool to room temperature

For greater detail on the procedure outlined above, consult the below PDF Regeneration Instruction. If you have further questions, please contact AGM!

Restrictions on Form Factor

As a pressed desiccant, H2OLock-ADV may be shaped to fit a customer’s individual requirements. In addition to standard shapes like pucks, cylinders, and tablets, the desiccant may be machined to create unique and complex shapes. As a result, H2OLock-ADV provides a tailored desiccant option for a wide range of project complexities.

H2OLock-ADV comes out of the press in either a cylindrical or prism format with two parallel faces. As for overall size limitations, the desiccant must fit into a 4.5 inch diameter cylinder and be no taller than 2 inches. Afterwards, it may be machined into almost any shape.

H2OLock-ADV Product Installation

H2OLock-ADV may be secured in place using screws and bolts, epoxy, or a combination of the two. The desiccant may be secured to PCB boards using the methods previously mentioned or placed into a fashioned holder to dry an enclosure.