Trouble finding a product?

Contact us.

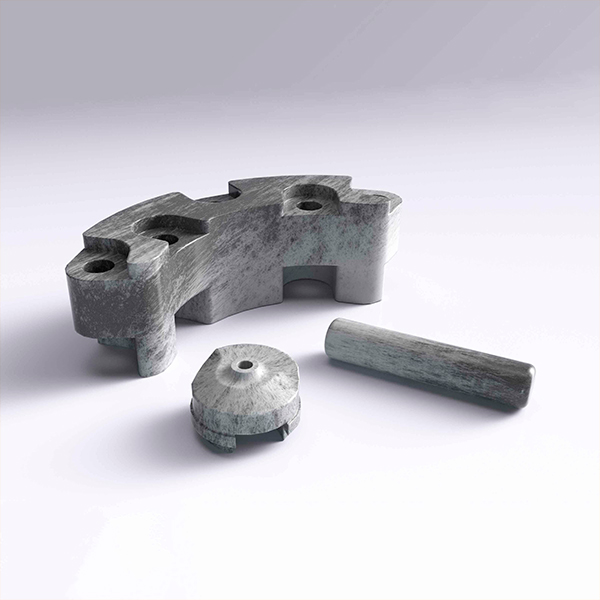

H2OLock-IMD Injection Molded Desiccants

Description

AGM’s H2OLock-IMD injection molded desiccant is made from a combination of 4A molecular sieve, nylon binder, and various other proprietary additives. As a result, the desiccant material is highly moldable, enabling the final product to conform to customer specified sizes, shapes and thicknesses. This combination of materials delivers optimized adsorption, strength, and form capabilities to best meet customer needs.

AGM’s custom molded desiccant can serve as a replacement for similar products sold through other manufacturers and distributors.

Key Features Include:

| PROPERTY | VALUE |

| Nominal Density (Dry) | 1.31 g /cc |

| Compressive Strength | 6000 PSI |

| Flexural Strength | 2000 PSI |

| Functional Moisture Capacity | 2.50 g / in3 |

| Maximum Service Temperature | 120°C (Continuous) |

| 200°C (Short Duration) |

Adsorption Rate

*Adsorption rate is affected by part geometry.

Why Use AGM Custom Molded Desiccants?

The benefit to using molded desiccants is found in their form factor and size. The desiccant is shaped using injection molding techniques and the material combination is such that the resulting desiccants are shaped to fit customer specifications, are strong enough for use as structural components in the design, and may be formed very small or to fit complex geometries.

Furthermore, due to the combination of materials employed in their manufacture, AGM’s molded desiccants provide an optimized moisture adsorption rate and capacity, while still delivering customer specific shaping options and crush strength.

4A molecular sieve is a high performance desiccant capable of delivering high capacity even at very low humidity. In addition, nylon is naturally hygroscopic, which serves to compliment the adsorptive capabilities of the molecular sieve and thus promote a high adsorptive capacity. Furthermore, nylon's high strength lends itself well to creating varying shapes and forms.