Trouble finding a product?

Contact us.

Vapor Phase Corrosion Inhibitors (VpCI)

Vapor Phase Corrosion Inhibitors (VpCI) can be used in packaging, coating and sealing to prevent rust and corrosion.

- Container Access

- Corrosion Prevention

- Humidity Monitoring

- Moisture Control

- Moisture Purging

- Pressure Control

- Shelving & Straps

- Shock Monitoring

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!

What are vapor phase corrosion Inhibitors (VpCIs)?

VpCI stands for Vapor phase Corrosion Inhibitors, a breakthrough technology where the corrosion inhibitor substance is transported to metal surfaces through a vapor phase instead of requiring actual contact with metal surfaces (as is typical with traditional VCIs).

Volatile corrosion inhibitors (VCI), also known as vapor phase corrosion inhibitors (VpCI), protect from rust and corrosion to ensure the integrity of any metal surface. VCIs are environmentally safe and do not contain nitrates or other harmful chemicals, providing exceptional product protection without the labor-intensive clean-up required with conventional oil coatings or other inhibiting products – even for previously corroded, painted or coated surfaces.

How do vapor phase corrosion inhibitors work?

Vapor phase corrosion inhibitors are chemicals that prevent water vapor from corroding metal components. VPCIs provide multi-metal protection with corrosion-inhibiting vapors that condense onto the surface of the metal and form a thin, uniform, molecular layer.

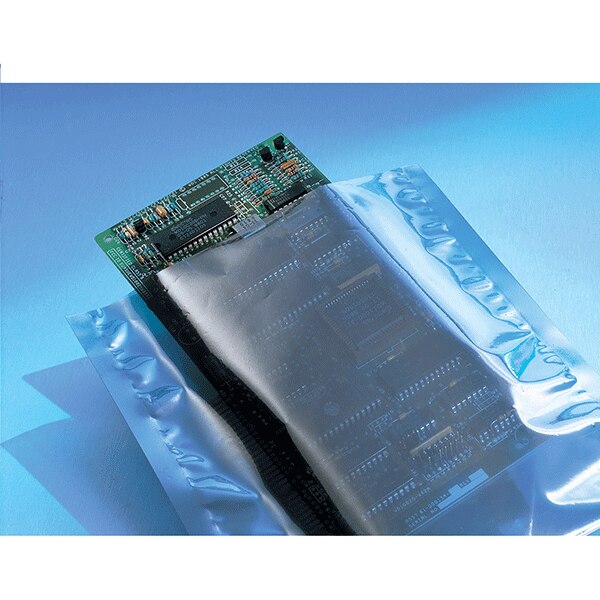

Paper and plastic bags used for shipping and storing metal components can be treated with these chemicals to prevent the corrosive effects of water vapor. While metal components are wrapped in paper or held in the bag, the VPCI chemicals will bond to the component surface in a thin, conformal molecular layer, thus preventing moisture.

VPCI is available as a paint-on primer or topcoat for metal that is continually exposed to an open environment, such as valves. The coverage is complete – all surfaces, including crevices, cavities and other inaccessible void areas receive total protection. The VCI barrier is self-replenishing, even for packaging that is repeatedly opened and typically protects for up to 24 months.

Benefits Of Using Vapor Phase Corrosion Inhibitors

VCI has many benefits such as:

- Saves costly time and labor

- No surface preparation required for application

- No cleaning / degreasing required for product use

- Reduces raw material requirements

- Need for oil is eliminated

- Desiccants are eliminated

- Eliminates disposal costs

- Products are fully recyclable

- No hazardous waste disposal costs

Our VpCIs have an industry-proven track record with over 20 years of application and testing experience to ensure reliable results. We provide multi-metal protection (for ferrous and non-ferrous metals) so that all contact areas are protected. Get a simple application that’s safe for personnel and the environment with non-toxic and recyclable materials. Contact us today to request a quote!

Vapor phase corrosion inhibitors are largely used in storing replacement parts for machines (e.g. aircraft engine components or machine dyes) as well as some tools. Because not all supplies will be used quickly or may be stored in humid locations, VPCIs provide a method of maintaining component integrity until the part is needed.

AGM offers custom engineering services so you can get exactly what you need.

FAQs

VpCI stands for “Vapor phase Corrosion Inhibitors” a breakthrough technology where the corrosion inhibitor substance is transported to metal surfaces through a vapor phase instead of requiring actual contact with metal surfaces (as is typical with traditional VCIs).

Our products are non-toxic and several substrates are completely recyclable; there are no hazardous waste disposal costs.

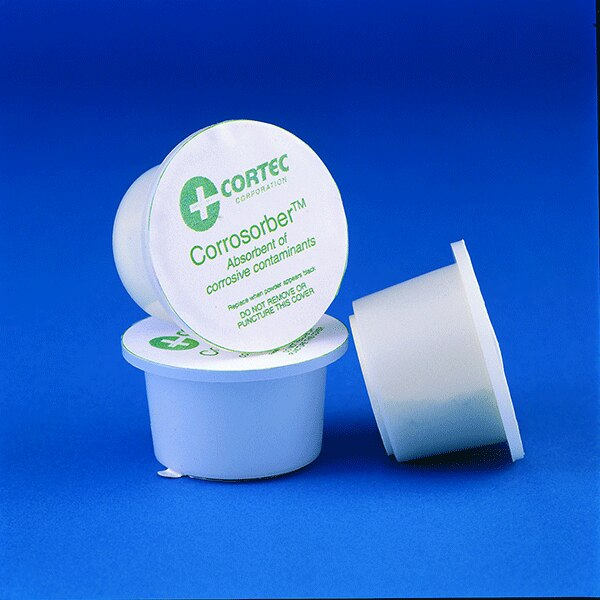

VpCI products are offered in a variety of formulations, including plastic films, papers, sprays, coatings, high density emitters, bubble and shrink wrap, liquid dips, liquid concentrate (water- and oil-based), grease, migratory power, and gel.

You may contact one of our Product Specialists at 520-412-7511, or send over information on your specific application on our contact page.

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!