Silica gel desiccants are common moisture adsorbing agents used throughout many industries worldwide. They have their own characteristics compared to other desiccants, that make them a go-to desiccant for almost any job. Nevertheless, there is sometimes some mystery surrounding silica gel that trips up everyone from do-it-yourself-ers to experienced engineers. This guide aims to fix that.

WHAT IS SILICA GEL AND HOW IS IT DIFFERENT FROM OTHER DESICCANTS?

Silica gel is a type of desiccant that is made from silicon dioxide, a natural compound found in sand and quartz. The chemical formula for silica gel is SiO2, where “SiO2” represents the chemical formula for silicon dioxide (also known as silica). It has several characteristics that distinguish it from other types of desiccants, including:

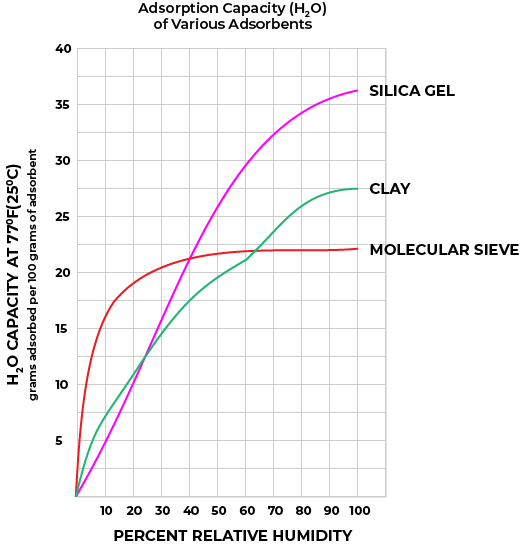

- High adsorption capacity: Silica gel is known for its high adsorption capacity, meaning it can adsorb and hold onto moisture more effectively than many other desiccants. This makes it a popular choice in applications where high humidity levels are a concern.

- Non-corrosive: Unlike some other desiccants, such as calcium chloride, silica gel is non-corrosive and will not damage or degrade the materials it comes into contact with.

- Non-toxic: White, non-indicating silica gel is also non-toxic, making it safe for use with some foods and pharmaceutical applications. However, this is not true of blue indicating silica gel.

- Regenerable: Silica gel can be regenerated for reuse by heating it to remove the moisture it has adsorbed. This makes it a cost-effective option for applications where desiccants need to be replaced frequently.

- Versatile: Silica gel is available in a variety of sizes, shapes, and configurations, making it a versatile desiccant that can be tailored to a wide range of applications.

Overall, silica gel is a highly effective and versatile desiccant that offers several advantages over other desiccant materials. Its high adsorption capacity, non-corrosive and non-toxic properties, regenerability, versatility, as well as affordability make it a popular choice in a wide range of industries and applications.

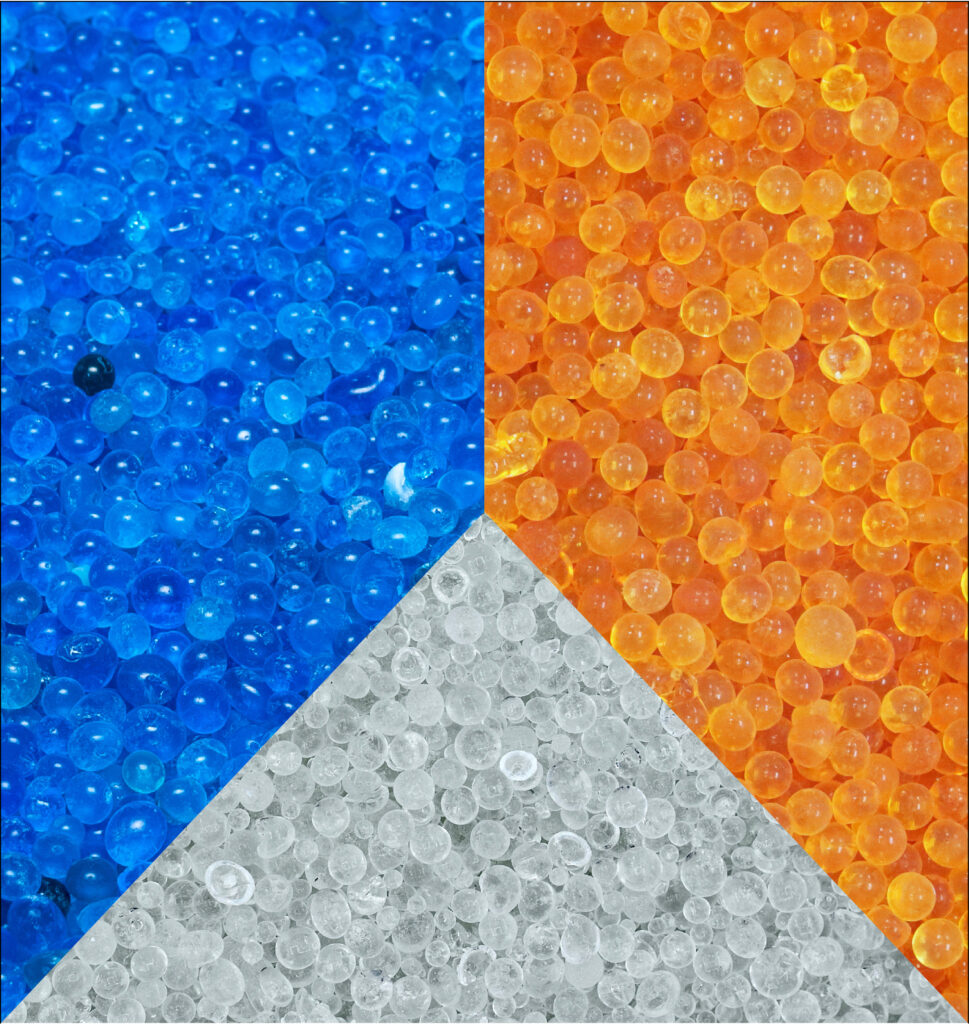

DIFFERENT TYPES OF SILICA GEL

There are many different types of silica gel, each with its own strengths; which type is best depends on the specifics of a given application. Contact AGM for help in determining which silica gel is right for yours.

Below are some different types of silica gel desiccants:

- Non-indicating silica gel: This is the most common type of silica gel desiccant, and it appears transparent or translucent when dry. It is often used in applications where there is no need to monitor the moisture level.

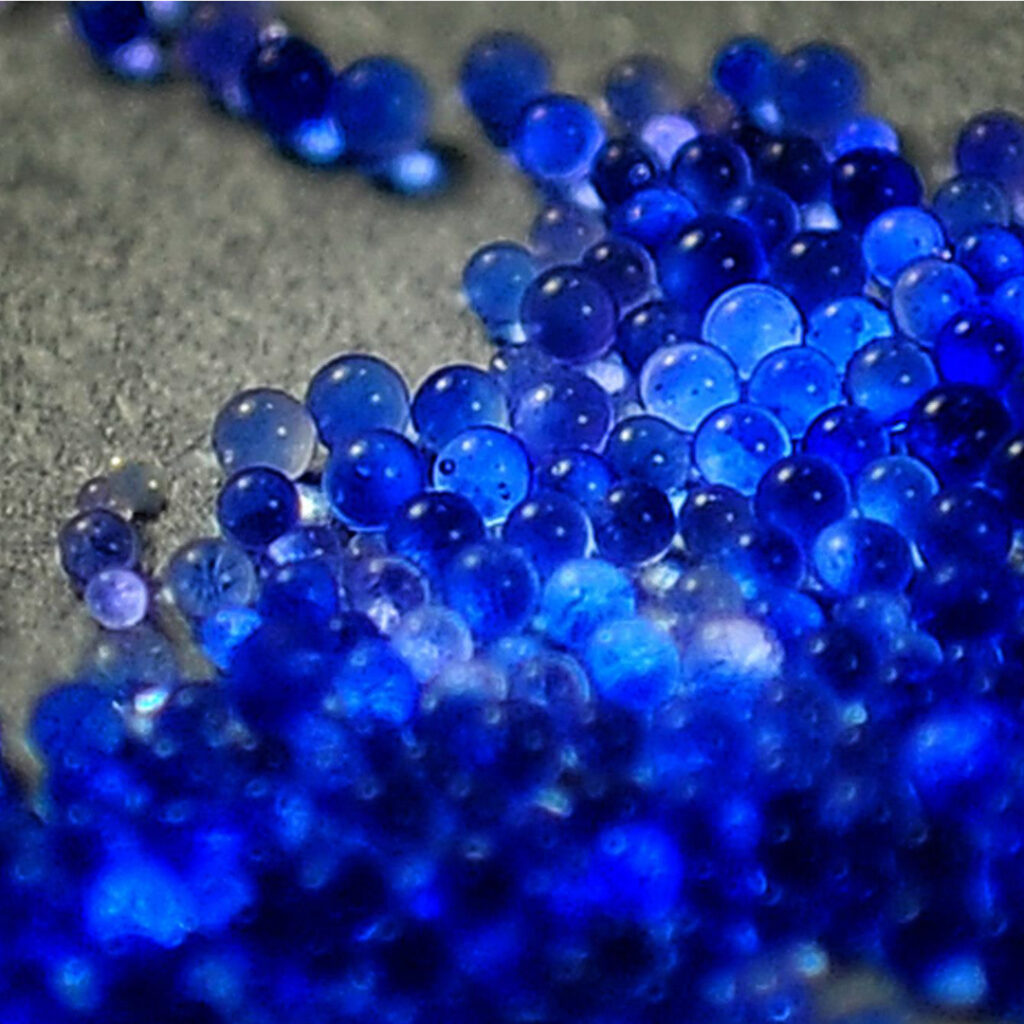

- Indicating silica gel: This type of silica gel contains an indicating agent that changes color when the silica gel becomes saturated with moisture. It is often used in applications where it is important to monitor the moisture level, such as in electronics or pharmaceuticals.

- Blue silica gel: This type of silica gel is impregnated with cobalt chloride, which is toxic. It appears blue when dry and changes to pink as it saturates with moisture.

- Orange silica gel: Similar to blue silica gel, orange silica gel is impregnated with methyl violet to create an indicating change. It appears orange when dry and changes to green as it saturates with moisture.

- Beaded silica gel: This type of silica gel is formed into small beads, which are often used in applications where a high surface area is needed.

- Granular silica gel: This type of silica gel is formed into larger granules, which are often used in applications where a slower rate of moisture adsorption is needed.

- Packaged silica gel: This type of silica gel is commonly non-indicating silica gel inside of sealed Tyvek®, kraft paper, or cloth packets and bags. They are often used in applications requiring desiccants to be tossed in or directly installed.

AGM’s Desiccant Guides

HOW MUCH WATER CAN SILICA GEL ADSORB?

In general, silica gel can adsorb up to 40% of its weight in water vapor before it becomes fully saturated – a state known as equilibrium. However, the time it takes for the silica gel to saturate depends on the specific conditions of its use. For example, if the silica gel is exposed to a high relative humidity environment, it will saturate more quickly than if it is exposed to a low relative humidity environment. Similarly, if the temperature is higher, the silica gel will saturate more quickly than if the temperature is lower.

It’s important to note that once silica gel is fully saturated, it will no longer be able to adsorb moisture. In fact, if the temperature is great enough, it can actually release moisture back into the air. For this reason, it’s important to monitor the silica gel’s saturation level and replace it or regenerate it as needed to ensure that it continues to be effective.

HOW DOES SILICA GEL WORK? (ADSORPTION)

Water molecules are held to to the surface of silica through a weak physical phenomenon known as adsorption. This process is different than that of absorption and involves the attraction and adherence of moisture molecules to the surface of the silica gel particles. The amount of water adsorbed onto the surface of the silica gel can vary depending on factors such as temperature, humidity, and the specific type of silica gel used.

Thanks to a great number of tiny pores, silica gel has a very high surface area, which is why it is able to adsorb large amounts of moisture relative to its weight. When the silica gel is exposed to a humid environment, moisture molecules from the air are attracted to the surface of the silica gel and adhere to the pores.

As more and more moisture is adsorbed, the silica gel eventually saturates. At this point, the silica gel will no longer be effective at adsorbing moisture and will need to be regenerated or replaced.

What is Adsorption?

Desiccants are materials that adsorb moisture from the surrounding environment, rather than absorb it. Adsorption is the process by which a material collects and holds onto molecules of another substance on its surface, while absorption is the process by which one substance is taken up by another substance throughout its volume.

WHY DOES SILICA GEL CHANGE COLOR?

Silica gel changes color to indicate saturation level. Orange and blue indicating silica gels are impregnated with specific chemicals to enable them to show color change with increasing saturation level. Conversely, non-indicating silica gel (known as white silica gel) is translucent and does not visibly show saturation level.

What Is The Color Of Silica Gel When It Is Dry?

Non-indicating silica gel will be white or translucent when dry. Conversely, blue indicating silica gel will appear a rich cobalt blue color, while orange indicating desiccant will be a vibrant orange.

What Color Is Silica Gel When It Is Saturated?

Indicating silica gel will change color completely once the desiccant is fully saturated. Blue indicating silica gel will turn pink, while orange indicating silica gel will turn green. It is worth noting, however, that during the saturation process, the desiccant will undergo shade transitions from blue to pink or orange to green to indicate an increasing level of saturation.

On the other hand, the saturation level of non-indicating silica gel is impossible to visually determine. However, including a humidity indicator card in the package with the desiccant provides a quick and easy visual identifier of saturation level. Additionally, the silica gel may be weighed, although this can be cumbersome and less than ideal. Alternatively, mark a time interval for change outs and follow a schedule. This time interval can be determined by an AGM engineer for complex applications. For everyday installs, an estimate is sufficient.

WHEN TO REPLACE SILICA GEL

A silica gel desiccant load should be replaced once the load is saturated. After a silica gel load has saturated, it will no longer adsorb moisture. In fact, if the temperature is great enough, it is possible for the silica gel to release its held moisture, potentially increasing the humidity in an environment it is supposed to protect.

HOW TO RECHARGE OR REGENERATE SILICA GEL?

Silica gel can be regenerated and reused many times. The process for regenerating silica gel involves removing the moisture that has been adsorbed onto the desiccant’s surface and restoring the gel to its original dry state. There are several methods for regenerating silica gel, including:

- Heating: Silica gel can be regenerated by heating it to a high temperature, typically between 100°C and 200°C, or about 212°F to 396°F. However, a maximum temperature of 130°C or 266°F is recommended*, as some silica gel can release toxic chemicals if overheated. Furthermore, the desiccant may be damaged and rendered unable to adsorb moisture. Nevertheless, heating the desiccant properly causes its adsorbed moisture to evaporate, leaving the silica gel dry and ready for reuse.

- Desiccant Dryers and Reactivators: Desiccant dryers are machines that use hot air to regenerate silica gel. The silica gel is placed in a container that is then heated with hot air, causing the moisture to evaporate and leaving the silica gel dry and ready for reuse.

*AGM does not recommend regenerating desiccants unless done by technicians experienced in the process.

Once the silica gel has been regenerated, it can be reused in the same way as before. The number of times silica gel can be regenerated depends on the specific manufacturing process, the purity of the gel, and the extent to which it has been used. Over time, the effectiveness of the silica gel may degrade, requiring replacement with new material.

However, it is worth noting that due to the low cost of silica gel and the comparative complexity of the regeneration process, silica gel is often simply replaced rather than regenerated, even in large-scale industrial applications.

HOW LONG DOES SILICA GEL LAST? (SHELF LIFE)

Typically, silica gel will last up to one year in its original packaging. However, this shelf life is dependent upon two factors:

- Storage conditions

- The packaging remaining unopened or uncompromised

AGM recommends that a storage environment remain between 0°F and 90°F (which is -17°C to 32°C), as well as keep humidity between 0% to 75% RH. Basically, store in a cool, dry place.

Additionally, if the packaging is opened or damaged, the desiccant will immediately begin adsorbing moisture from the ambient air. Therefore, the packaging must remain sealed to achieve the maximum possible shelf life.

DESICCANT UNIT CALCULATION FORMULA

There is no one formula for calculating a silica gel amount; rather, there are several calculations involved in order to achieve accurate figures. However, a general rule of thumb is to include 1.2 units of desiccant per cubic foot of air volume to be protected. Due to the adsorption rates of different desiccants varying, this rule generates different amounts for different desiccants.

To make things easier, AGM provides a free Desiccant Unit Calculator for use in estimation. Simply plug in your units of measure and the total volume in need of protection and the calculator provides desiccant unit amounts for three different desiccants.

AGM SILICA GEL DESICCANTS

As a supplier of desiccant products since 1970, AGM knows what it takes to ensure the success of both simple and complex moisture control systems. So when you need silica gel desiccants, choose AGM.

Contact AGM for assistance in specifying desiccant solutions for your project. Find the Custom Desiccant form here or email AGM Engineering.