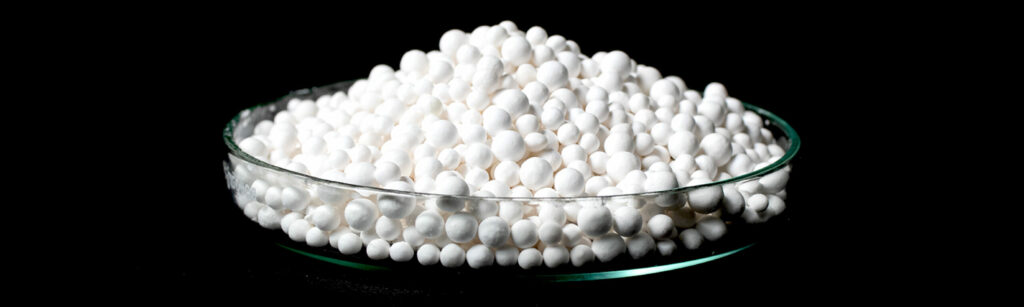

More than your standard desiccant, activated alumina is known for its ability to effectively dry and purify liquids and gases.

What Is Activated Alumina?

Activated alumina is a type of desiccant that is commonly used to remove moisture and impurities from gases and liquids. It is made from aluminum oxide (Al2O3), which is heated to produce a highly porous material.

Notable Characteristics

- Crush Strength: The adsorbent’s high crush strength makes it suitable for work in high pressure and extreme environments.

- Filtration: As a polar adsorbent, activated alumina will preferentially adsorb molecules with the greatest polarity, making it effective in column chromatography.

- Surface Area: Depending on its type, activated alumina can have a surface area greater than 300 m^2/g

- Low Dewpoint Capable: Depending on operating conditions, activated alumina can achieve dew points as low as -40°F (-40°C).

What Is Activated Alumina Used For?

Broadly, AGM recommends activated alumina desiccant in cyclical applications, such as when a desiccant is repeatedly saturated and regenerated. Use in regenerative dryers is a common example. Gas separation is another frequent application of activated alumina; however, the desiccant has many varied uses, including:

- Compressed air systems, where it is commonly used to remove moisture from the air before it enters the system, thus preventing corrosion, rust, and associated damage.

- Dehumidification applications, such as in refrigerant dryers, where the adsorbent is used to remove moisture. This is important in industries where humidity control is critical, such as in food and pharmaceuticals.

- Chemical and petrochemical industries, where activated alumina is used to remove moisture from gases and liquids, which can cause corrosion and other issues in pipelines and processing equipment.

- Electronics manufacturing, to prevent moisture from damaging sensitive components, such as in the production of semiconductors and printed circuit boards.

- Packaging, where the desiccant is used in packaging to prevent moisture damage to products during shipping and storage.

- Storage and preservation, to preserve and extend the shelf life of various products, such as in the storage of seeds, flowers, and other perishable items.

- Water purification, where activated alumina may be used to purify water and remove fluoride, arsenic, and selenium.

- Degradation removal, where it is possible for activated alumina to remove degradation acids from transformer oils, lubricating oils, and refrigerants.

How Much Water Will Activated Alumina Desiccant Adsorb?

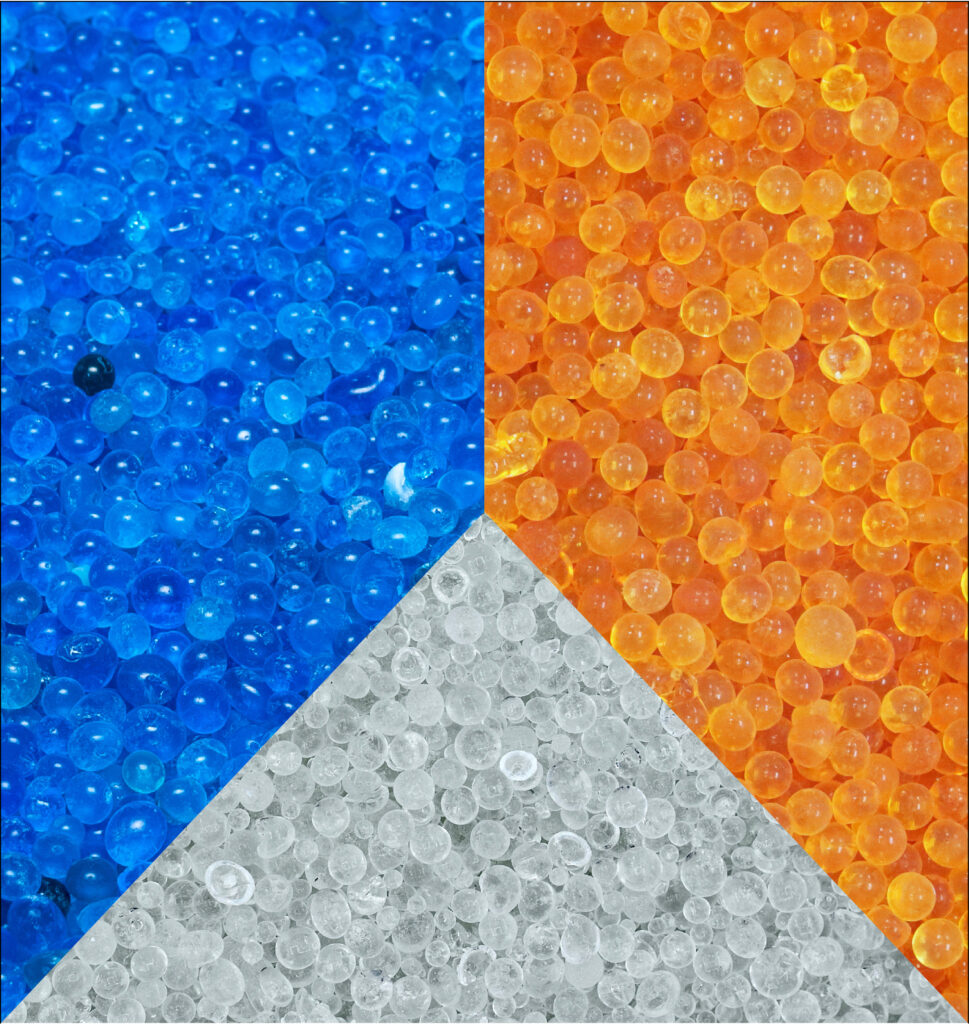

The amount of water that activated alumina will adsorb before it becomes saturated will depend on various factors such as the surface area of the material, the pore size, the relative humidity of the surrounding environment, and the temperature. However, activated alumina typically adsorbs less water than silica gel and molecular sieve.

Broadly speaking, activated alumina can adsorb up to approximately 20% of its weight in water. However, this varies depending on the specific type of activated alumina and the conditions of use.

It’s also important to note that desiccant-load replacement is commonly prescribed for when the relative humidity of a desiccated environment reaches some chosen threshold. Desiccant amounts and types for a given application are calculated based on the demands of a system; therefore, once the RH of that system begins to rise, it may be surmised that the desiccant is saturating or has saturated to a point of inefficiency.

Further, once desiccant becomes saturated, it will no longer be effective at adsorbing moisture. Therefore, it’s important to monitor the saturation level of the activated alumina or monitor the RH of the enclosure, and replace the desiccant or regenerate it as needed to ensure that it continues to be effective. This is frequently done using a humidity indicator card.

AGM’s Desiccant Guides

For information about other kinds of desiccants, check out AGM’s desiccant guides.

Toxicity And Safe Handling Of Activated Alumina Desiccant

Activated alumina is generally considered non-toxic, as it is an inert material that does not react with most chemicals. However, as with any material, there may be some risks associated with exposure to activated alumina, particularly if it is inhaled as dust or ingested in large quantities.

Storage Conditions: How To Store Activated Alumina Desiccant

As with all of the bulk desiccants that AGM markets, it’s recommended to store activated alumina in metal cans at room temperature (60°F – 80°F or 15°C – 26°C) with humidity between 0% and 70% RH.

What Is The Shelf Life Of Activated Alumina Desiccant?

AGM guarantees shelf life up to 1-year for all desiccants it markets, provided the desiccant is kept in uncompromised, original packaging, and stored in optimal conditions. If you need greater shelf life, contact AGM.

How Much Desiccant Do You Need?

Check out AGM’s Desiccant Unit Calculator for a broad understanding of how many units of a particular desiccant a project needs based on the volume of space in need of protection. Additionally, try AGM’s Humidity Calculator to get a better sense of your project’s environment. When used together, the two calculators provide a broad level idea of your protection needs.

For projects with high sensitivity that require precision solutions, contact AGM and speak with an engineer. AGM’s expertise in adsorbents has continued to safeguard the aerospace industry since 1970.

How To Make Activated Alumina Desiccant

The equipment and processes used to manufacture activated alumina are expensive and potentially hazardous. As such, AGM does not recommend attempting to make the desiccant by anyone other than qualified persons. Therefore, the process described below for making activated alumina desiccant is intended for informational purposes only and may not be complete.

- Raw Material Preparation: The raw material used in the production of activated alumina is typically aluminum hydroxide. The aluminum hydroxide is processed to remove impurities and then ground into a fine powder.

- Activation: Activation involves subjecting the powder to temperatures nearing 1000°C. This high-temperature treatment causes the aluminum hydroxide to undergo a phase change and transform into gamma alumina, which has a larger surface area and greater porosity.

- Impregnation: After activation, the gamma alumina is impregnated with a chemical solution that enhances its moisture-adsorbing properties. Common impregnating agents include phosphoric acid, potassium permanganate, and sodium hydroxide. The choice of impregnating agent depends on the specific application of the activated alumina.

- Drying and Packaging: The final step in the manufacturing process is drying and packaging the activated alumina desiccant. The impregnated gamma alumina is typically dried in a rotary kiln to remove any residual moisture. The dried activated alumina is then packed in bags or drums and shipped to customers.

Conclusion

AGM has supplied desiccants to industries across the globe since 1970. Our engineering department regularly consults with industry engineers to design and manufacture custom solutions for highly sensitive and complex projects, such as aerial optics, large- and small-launch rocket fuel tanks, and much more.

For help protecting your project, contact AGM engineers today.