What is Desiccant Equilibrium Capacity?

Desiccant equilibrium capacity, or saturation is the point at which a desiccant can no longer adsorb water vapor from the air at a given relative humidity.

Once a desiccant’s equilibrium capacity has been achieved (the desiccant has saturated), all or most of its active pore sites are filled with water molecules, which are normally held in the pores by atomic bonds. In other words, a given desiccant simply has no more active pore sites in which water molecules may be captured. At this point, a desiccant cannot adsorb more water vapor.

Once a desiccant has reached its saturation point, water molecules begin to exchange between the desiccant and the surrounding environment. If temperatures increase in a desiccated space, the bonds that hold water molecules to a desiccant weaken, and water molecules will release from a desiccant at a greater and greater rate.

Find Your Desiccant with Selecting The Right Desiccant

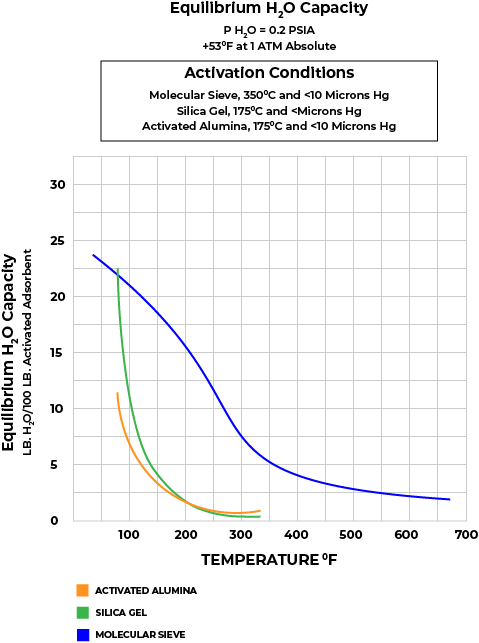

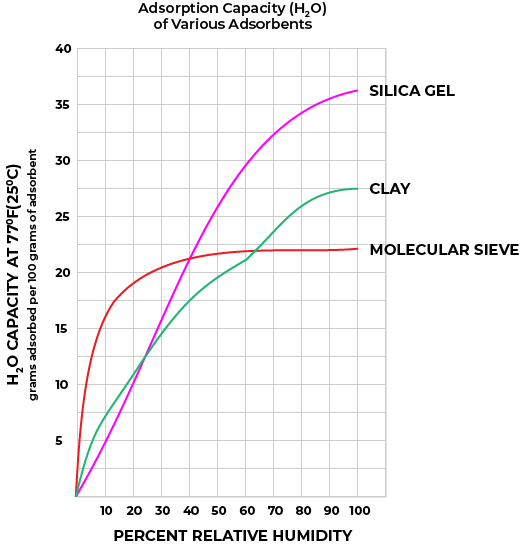

Each type of desiccant has a different equilibrium capacity and adsorption rate dependent upon the temperature and humidity of its surrounding environment. For example, in an environment with temperatures less than ~100°F and high relative humidity, silica gel features the highest equilibrium capacity. Comparatively, in high temperature and low humidity environments, molecular sieve performs better. Learn how sorption works in this video.

Desiccant Maximum Capacity

In addition to equilibrium capacity, each desiccant type has an overall maximum capacity, which is the total capacity one can expect under ideal performance scenarios. This maximum capacity is theoretical at best, and the consumer should not perform calculations based on the maximum capacity. AGM Engineering recommends reducing the graphed capacity by approximately 2- to 4-percent to account for adsorption that occurs during shipping and handling.

The following graph illustrates the adsorption rate and capacity as a function of the ambient humidity level:

When determining which desiccant is right for your project, it is important to balance a desiccant’s adsorptive capabilities with your needs to achieve appropriate moisture protection for the least cost possible. For example, if your project requires an extremely dry environment (<= -40°C Dewpoint) – such as in the case of missiles, seeker assemblies, and many other aerospace, military, and space technologies – then a molecular sieve desiccant is likely the best option. However, if your project does not need quite as dry of an environment (<= -20°C dewpoint), clay or silica gel may be more appropriate.

The graph below illustrates desiccant equilibrium capacity for water as a function of temperature increase:

Contact Us

If you have questions regarding desiccant solutions for your project, call AGM at (520) 881-2130, or email AGM’s engineering team.