Trouble finding a product?

Contact us.

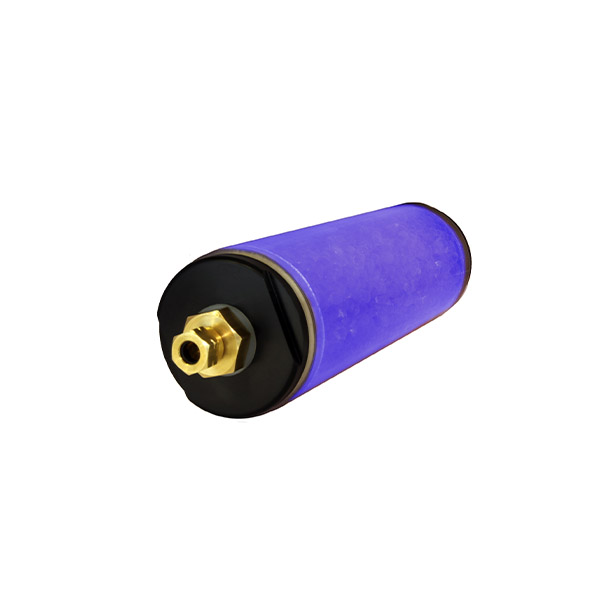

In-Line Desiccators

In-Line Desiccators maintain low dew point temperatures in compressed air or process gas pipelines and reduce water vapor content to a safe level in systems with working pressures up to 60 psi.

- Container Access

- Corrosion Prevention

- Humidity Monitoring

- Moisture Control

- Moisture Purging

- Pressure Control

- Shelving & Straps

- Shock Monitoring

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!

What are in-line desiccators?

In-line desiccators are desiccant-filled canisters that are intended for installation in what is often a pressurized gas line of one type or another. In-line desiccators scrub moisture vapor from the air as it passes through the canister on its way to wherever else.

How do in-line desiccators work?

Low dew point temperatures are maintained in compressed air or process gas pipelines up to 1/4″ outside diameter by fitting in-line desiccators to reduce water vapor content to a safe level in systems with working pressures up to 60 psi.

While primarily used to remove water vapor as the prime source of contamination, the selective adsorption of other components of the gas can be achieved by careful selection of the grade and pore size of the molecular sieve desiccant.

Various grades of filters may be fitted in the dry gas outlet side of the dryer to ensure that the gas is cleaned to a specified level before it re-enters the gas line. Particulate cleanliness to below 1µm can be maintained by using special filters.

Actual water vapor content must be measured wherever dew point temperature or maximum water vapor concentration is specified and necessitates the use of a line dryer. Fitting a color-change Humidity Indicator signals when the maximum safe water vapor concentration of 2,560 ppmV at STP (about 14°F [-10°C] dew point). An in-line dew point temperature alarm should be fitted if the safe level required is lower than 2,500 ppmV.

Benefits Of In-Line Desiccators For Moisture Control

The primary benefit of using in-line desiccators is simply that they remove moisture from a gas.

Industry Applications

Desiccators are used in a wide variety of applications including:

- Waste-to-energy

- Aerospace

- Defense

- Chemical

- Storage

- Disposal

- Oil and Gas

Contact us to find out if our in-line desiccators are the right solution for your application.

Custom Engineering Service

No two jobs are the same so get the solution that’s right for you. Work with AGM Engineering and get a solution specific to your challenge today.

FAQs

Yes, our in-line desiccators may be used with compressed air as well as with most other compressed process gasses.

Some of our in-line desiccators units are available with pressure ratings as high as 60 psig.

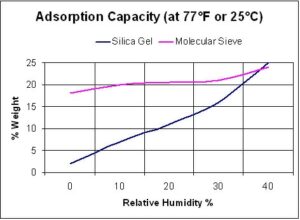

Yes. These units are available filled with molecular sieve, silica gel, or alumina. However, Type 4A molecular sieve is by far the most commonly requested desiccant for these units. AGM carries a full line of desiccant products and can supply replacement desiccant for pipeline dryers.

Yes. The outlets on most units are filtered nominally to 25 microns, but finer filters are also available upon request.

Yes. However, some fittings might require the use of special adapters.

Yes. By simply unscrewing the inlet end fitting, the old spent desiccant may be poured out and fresh, new desiccant poured in. We carry a full line of desiccant products and can supply replacement desiccant for pipeline dryers.

Drop-in cartridges are not available for these units at this time but may become available in the future.

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!