Trouble finding a product?

Contact us.

Cartridge-Style Breathing Desiccators

Description

Cartridge-Style Breathing Desiccators - effective drying in a small package

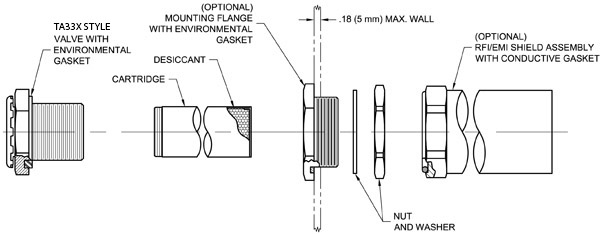

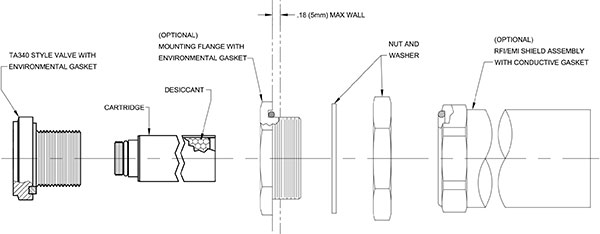

A breathing desiccator is a non-powered, compact device for minimizing moisture and relieving pressure buildup inside an enclosure. It consists of a replaceable desiccant cartridge attached to a breather valve. Air that enters through the breather valve is immediately dried as it flows through the desiccant, keeping the contents of the enclosure as dry as possible.

Standard desiccant cartridges are available for many AGM breather valves: TA225, TA225-R, TA330, TA333-R, TA340-R, and TA341-R. The TA340-R and TA341-R valves are a popular choice because they include visual humidity indication, thereby providing a visual indication if the humidity level inside the enclosure is dangerously high.

The desiccant cartridge has porous plastic walls for fast moisture adsorption and a moderate pressure drop. The typical airflow rate through a breathing desiccator is 25%-33% of the flow rate through the valve by itself (see individual valve pages for valve flow rates). The desiccant cartridge is constructed of inert materials for simple disposal.

Standard desiccant cartridges are available in lengths of up to six inches. Each inch of cartridge length for TA330/TA333 and TA340/TA341 breathing desiccators holds approximately 6 grams (0.21 ounces) of silica gel or molecular sieve desiccant. Each inch of cartridge length for TA225/TA225-R breathing desiccators holds approximately 0.8 grams (.03 ounces) of desiccant.

An optional AGM mounting flange makes installation and removal of the breathing desiccator simple. The desiccant cartridge can be replaced without opening the lid of the enclosure, thereby saving time and minimizing moisture entry into the enclosure.

For applications requiring RFI/EMI protection, an optional RFI/EMI shielded nut assembly installs on the back of the mounting flange. The length of the RFI/EMI shielded nut assembly depends upon the length of the desiccant cartridge.

AGM's Engineering Department specializes in assisting customers in finding the correct valve settings for each application, as well as estimating how much moisture will be drawn into an enclosure during air flight, ground transport, or storage. Contact AGM’s Engineering Department for help.