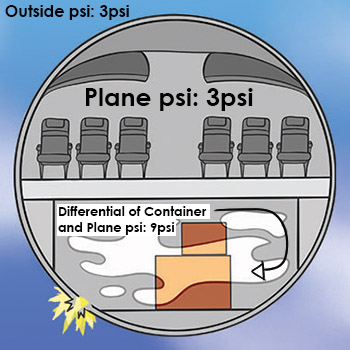

The dangers of rapid decompression and high pressure differentials

Rapid decompression can create dangerous pressure differentials in a fraction of a second. Such differentials cause sealed cargo containers to rupture or explode if the pressure is not quickly relieved and brought to a tolerable level. As a result, cargo containers, their contents, and the aircraft can be damaged, or the plane’s occupants injured.

What to do about it? agm’s ultra high-flow pressure relief valves

Commonly referred to as magnet valves, AGM’s Ultra-High-Flow Relief Valves are magnetically actuated to provide flow rates specifically capable of venting a container to relieve catastrophic pressure buildup during decompression events. Unlike conventional spring-actuated valves, AGM magnet valves fully open once the desired pressure threshold is reached, to achieve full air-flow almost instantly.

Due to their superior performance, agm magnet valves:

- Relieve pressure in about one-fifth the time compared to spring-actuated valves

- Provide Dramatically higher air-flow rates at any given pressure differential compared to spring-actuated valves

- Are capable of relieving catastrophic pressure with a single valve per container

- Enable smaller, lighter, and ultimately less expensive container construction

- Magnets do not interfere with aircraft navigation and control systems