Trouble finding a product?

Contact us.

Breather Valve TA292-R

Description

The TA292-R Breather Valve was designed to meet the need for a low cost, two-way valve for use on transit cases and similar applications up to 4 cubic feet in volume. The valve has separate and distinct settings for both pressure and vacuum relief. It has a flow rate of 0.5 SCFM at a pressure of 1.5 psi to 2.0 psi above the valve setting. Standard settings range from 0.5 psid to 3.0 psid reseal pressure.

The TA292-R Breather Valve is tamper-proof and requires no field maintenance. Corrosion-resistant materials are used throughout. The valve seal is made of silicone rubber. Each valve comes complete with a nut and o-ring, and is intended for small cases that require a low profile valve. A manual release push button is standard on all TA292-R valves. It is used to equalize pressure or vacuum differentials in order to open the container.

| Materials | Housing & Hex Nut - Aluminum Alloy, O-Ring - per MS28775-018 |

| Finish | Black Anodize |

| Mounting Requirements | Hex nut & an O-ring provided with each valve* |

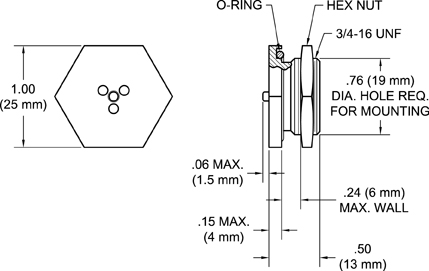

| Mounting Hole Diameter | 0.76 ± 0.010 (19.3 ± 0.2 mm) |

| Maximum Wall Thickness | 0.24 (6 mm) |

| Installation Torque | 25-35 in. - lbs. (3.0-4.0 Nm) |

| Weight | 0.02 lbs. (8.4 grams) |

*Add washer for wall thickness less than: 0.05 (1.3 mm). (AGM P/N 196284, order separately.)

For threaded boss installation: 0.750-16 UNF-3B; no counterbore requirement.

Contact AGM's Engineering department for information on NEMA and IP ratings.

Two-Way Pressure and Vacuum Relief Valves

|

PRESSURE SIDE (FLOW OUT)

|

VACUUM SIDE (FLOW IN)

|

||||

|

Dash No.

|

Sealed @

|

Flow Rate @ Pressure

|

Dash No.

|

Sealed @

|

Flow Rate @ Pressure

|

|

-05

|

0.5 psid*

|

0.5 SCFM† @ 2.0 psid*

|

-05

|

0.5 psid*

|

0.5 SCFM† @ 2.0 psid*

|

|

-10

|

1.0 psid*

|

0.5 SCFM† @ 2.5 psid*

|

-10

|

1.0 psid*

|

0.5 SCFM† @ 2.5 psid*

|

|

-15

|

1.5 psid*

|

0.5 SCFM† @ 3.0 psid*

|

-15

|

1.5 psid*

|

0.5 SCFM† @ 3.0 psid*

|

|

-20

|

2.0 psid*

|

0.5 SCFM† @ 3.5 psid*

|

-20

|

2.0 psid*

|

0.5 SCFM† @ 3.5 psid*

|

|

-25

|

2.5 psid*

|

0.5 SCFM† @ 4.5 psid*

|

-25

|

2.5 psid*

|

0.5 SCFM† @ 4.5 psid*

|

|

-30

|

3.0 psid*

|

0.5 SCFM† @ 5.0 psid*

|

-30

|

3.0 psid*

|

0.5 SCFM† @ 5.0 psid*

|

*To convert to metric equivalent (millibars) multiply by 69.

†To convert metric equivalent (liters/sec) multiply by 0.472.

Dash numbers for the Pressure and Vacuum sides may be used in any combination (i.e. TA292-05-15-R). Before making drawings of these valves, contact AGM for part numbers to be used.

One-Way Pressure or Vacuum Relief Valves

While typically configured as a two-way valve, this valve can also be configured for one-way flow. Refer to the TA292-P and TA292-VR drawings. The vacuum relief version of the valve includes a manual release, but the pressure relief version does not. Contact AGM's Engineering Department for assistance, if needed.

|

PRESSURE SIDE (FLOW OUT)

|

VACUUM SIDE (FLOW IN)

|

||||

|

Dash No.

|

Reseal Pressure*

|

Flow Rate*

|

Dash No.

|

Reseal Pressure*

|

Flow Rate*

|

|

-P-025

|

0.25 psid

|

0.5 SCFM† @ 1.75 psid

|

-VR-025

|

0.25 psid

|

0.5 SCFM† @ 1.75 psid

|

|

-P-05

|

0.5 psid

|

0.5 SCFM† @ 2.0 psid

|

-VR-05

|

0.5 psid

|

0.5 SCFM† @ 2.0 psid

|

|

-P-10

|

1.0 psid

|

0.5 SCFM† @ 2.5 psid

|

-VR-10

|

1.0 psid

|

0.5 SCFM† @ 2.5 psid

|

|

-P-15

|

1.5 psid

|

0.5 SCFM† @ 3.0 psid

|

-VR-15

|

1.5 psid

|

0.5 SCFM† @ 3.0 psid

|

|

-P-20

|

2.0 psid

|

0.5 SCFM† @ 3.5 psid

|

-VR-20

|

2.0 psid

|

0.5 SCFM† @ 3.5 psid

|

|

-P-25

|

2.5 psid

|

0.5 SCFM† @ 4.5 psid

|

-VR-25

|

2.5 psid

|

0.5 SCFM† @ 4.5 psid

|

|

-P-30

|

3.0 psid

|

0.5 SCFM† @ 5.0 psid

|

-VR-30

|

3.0 psid

|

0.5 SCFM† @ 5.0 psid

|

*To convert to metric equivalent (millibars) multiply by 69.

†To convert metric equivalent (liters/sec) multiply by 0.472.

Contact AGM for availability of part numbers and settings in addition to those shown on the drawings.

Additional Information

| Materials | Housing & Hex Nut-Aluminum Alloy, O-Ring-per MS28775-018 |

|---|---|

| Finish | Black Anodize |

| Mounting Requirements | O-Ring & Hex Nut are provided with each valve |

| Mounting Hole Diameter | 0.76 ± 0.010 (19.3 ± 0.2 mm) |

| Maximum Wall Thickness | 0.24 in. (6 mm) |

| Installation Torque | 25-35 in. – lbs. (3.0-4.0 N-m) |

| Weight | 0.02 lbs. (8.4 grams) |