Trouble finding a product?

Contact us.

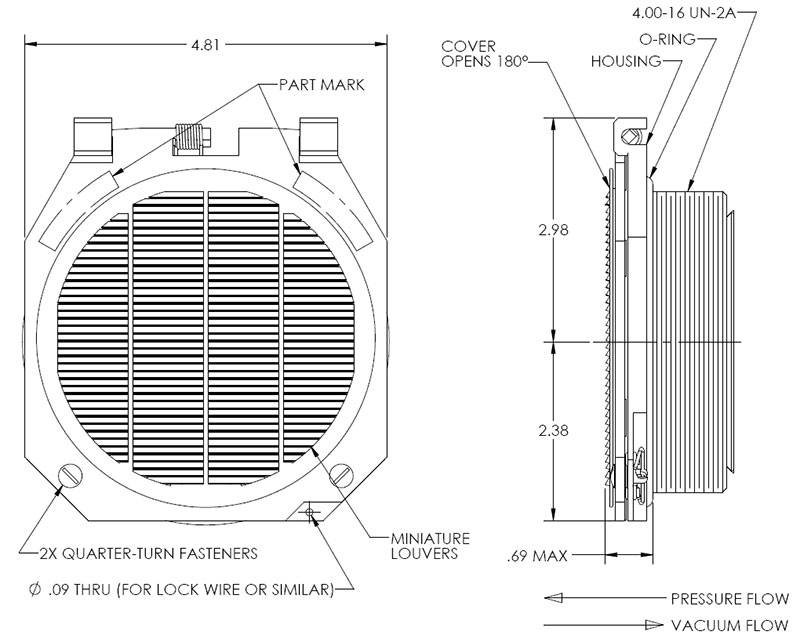

Breather Valve TA820

Description

The TA820 two-way breather valve provides moderate to high flow and reliable operation at very low opening pressures in the range of 1-3 inches wc. This combination of characteristics makes it ideal for large enclosures such as military shelters or large shipping/storage containers that require protection from the pressure differentials that arise from air transport, daily variation in temperature and atmospheric pressure, and the opening and closing of the enclosure door.

The TA820 features a flip-open cover with a micro-louvered aluminum screen. Releasing the two quarter-turn fasteners allows the cover to flip open for manual pressure and vacuum relief or inspection of the valve internals. The TA820 breather valve will protect against rain, but not against water intrusion from a high-pressure hose down.

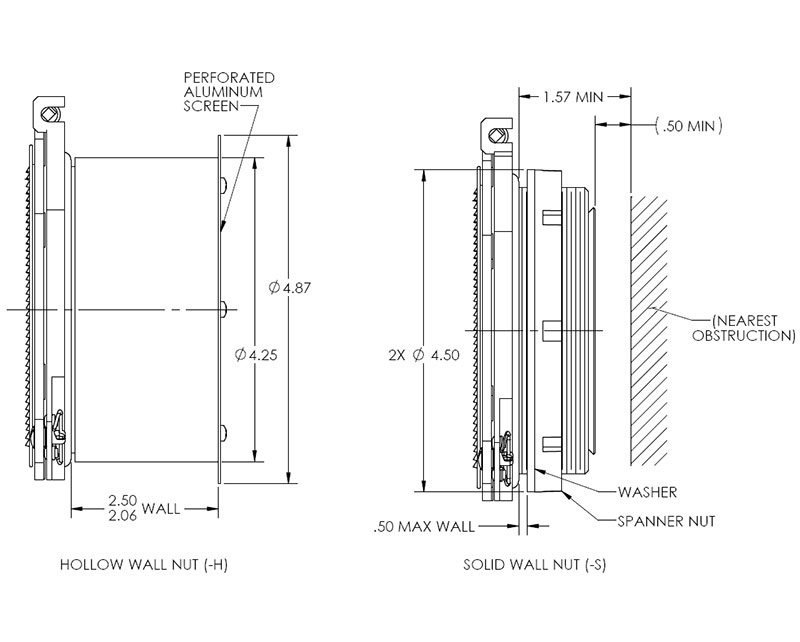

For solid wall applications (-S), the valve is provided with a spanner nut and washer. For thick, hollow wall applications, the body of the hollow wall nut (-H) recesses into the wall, presenting a nearly flush surface on the inside of the container. The perforated aluminum screen on the hollow wall nut prevents interference with the valve internals, and provides some RFI/EMI shielding. Where needed, AGM can provide a fully RFI/EMI shielded solution. For applications where particle ingress is a concern, filtration is also available.

Please contact AGM for details. Before making drawings of these valves, contact AGM for part numbers to be used.

|

PRESSURE SIDE (FLOW OUT)*

|

VACUUM SIDE (FLOW IN)*

|

||||||

|

Crack

|

Reseal

|

Min. Flow

|

Crack

|

Reseal

|

Min. Flow

|

Mounting Hardware

|

|

|

Part No.

|

in. wc

|

in. wc

|

SCFM at in. wc

|

in. wc

|

in. wc

|

SCFM at in. wc

|

(See Below)

|

|

TA820-10W-10W-H

|

1.0 ±.5

|

.5

|

55 at 3.0

|

1.0 ±.5

|

.5

|

55 at 3.0

|

-H

|

|

TA820-10W-10W-S

|

1.0 ±.5

|

.5

|

55 at 3.0

|

1.0 ±.5

|

.5

|

55 at 3.0

|

-S

|

* Custom settings available. Higher settings require greater pressure differentials to achieve rated flow.

| Materials | Housing, Cover, Nut: Aluminum Internal Components: PVC, Nylon Springs, Fasteners: Stainless Steel Seals: Neoprene Rubber O-ring: IAW MS28775 |

| Finish | Aluminum: Black Anodized Aluminum Washer: Clear Anodized Perf. Al. Screen: Conversion Coat, RoHS Compliant Stainless Steel: Passivated |

| Mounting Orientation | Vertical Wall (Horizontal Flow Path) |

| Mounting Hardware | Hollow Wall (-H): Gasket and flush nut provided Single Solid Wall (-S): Gasket, washer, and spanner nut provided |

| Installation Torque | 150 in. - lbs. |

| Mounting Hole Diameter (Outer Wall of Container) | 4.05 ± .02 inches |

| Clearance Hole Diameter, Inner Face of Hollow Wall | 4.30 ± .02 inches |

| Maximum Hollow Wall Thickness† | 2.50 inches |

| Minimum Hollow Wall Thickness† | 2.06 inches |

| Maximum Solid Wall Thickness† | 0.50 inches |

| Weight | 1.25 pounds |

† Configurations for different wall geometries available.

Additional Information

| Materials | Housing, Cover & Nut-Aluminum, Internal Components-PVC & Nylon, Springs & Fasteners-Stainless Steel, Seals-Neoprene Rubber, O-Ring-IAW MS28775 |

|---|---|

| Finish | Aluminum-Black Anodized, Aluminum Washer-Clear Anodized, Perf. AI. Screen-Conversion Coat, RoHS Compliant, Stainless Steel-Passivated |

| Mounting Orientation | Vertical Wall (Horizontal Flow Path) |

| Mounting Hardware | Hollow Wall(-H)-Gasket & flush nut provided, Single Solid Wall (-S)-Gasket, washer & spanner nut provided |

| Installation Torque | 150 in. – lbs. |

| Mounting Hole Diameter (Outer Wall of Container) | 4.05 ± .02 inches |

| Clearance Hole Diameter, Inner Face of Hollow Wall | 4.30 ± .02 inches |

| Maximum Hollow Wall Thickness | 2.50 inches |

| Minimum Hollow Wall Thickness | 2.06 inches |

| Maximum Solid Wall Thickness | 0.50 inches |

| Weight | 1.25 lbs. |