Trouble finding a product?

Contact us.

About Us

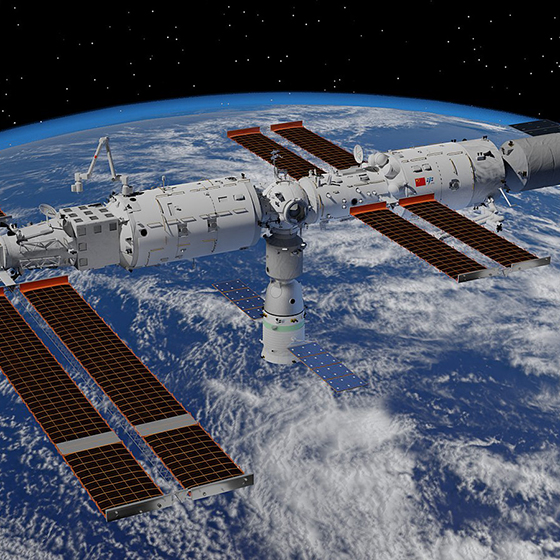

AGM aspires to be a model, principled company with a mission to meet the needs of our nation’s national defense efforts, as well as those of the aerospace, space and technical industries. Perhaps most importantly, however, AGM strives to be a positive supporter of its local community.

Our Story

In 1955, Harrison Browning founded Arizona Gear and Manufacturing, which was the first company to design breather valves for Hughes Aircraft missile containers. Following this success, in 1970, Roger and Joyce Stewart bought a branch of Arizona Gear that eventually turned into AGM Container Controls. Thanks to the Stewarts’ vision, AGM has become a growing family of brands delivering a wide range of products and solutions for the Aerospace, Defense, Manufacturing and Accessibility markets.

Our Values

AGM is the subject matter expert on protecting contained environments. Diligently maintaining a robust, AS9100-certified quality system, our AGM employee-owners strive for exceptional product quality and on-time delivery performance. In addition, our AGM design engineers work directly with our customers to specify products that best suit their given application.

We are an active member of our local community

Headquartered in Tucson, AGM supports numerous charities and events throughout the year. In 2009, AGM was recognized with the national U.S. Chamber of Commerce’s “America’s Best Small Business of the Year” award.

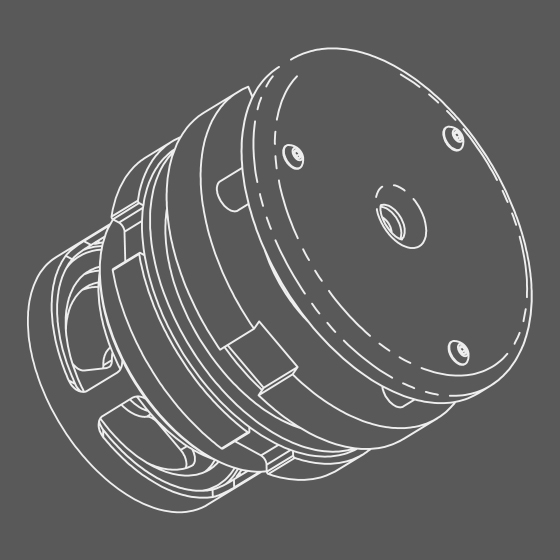

The AGM Family Of Brands

Our Team

AGM maintains a five-member board of directors overseeing all aspects of the company’s health and business direction.

Come Join Our Team

Come Join Our Team! AGM is always interested in finding new talent to help grow our company. Click the button below to see current openings.

What to Expect When Working With AGM

How does the quote process work? Need help prototyping? Interested in machining services? From research to final product and everything in between, learn about what it’s like working with AGM.

Foreign Distributors

AGM works with many distributors around the world to ensure that you can get the products you need in the easiest way possible.

Find What You're Looking For

It’s a lot, we know. If you’re looking for something specific or aren’t sure what you need, try searching through all products or give us a shout and we’ll help!